Picture the fulfillment warehouse of the near future. Much like what is already happening today, robots will traverse the aisles, picking and packing goods for shipment. What’s different in this world is, when one of the robots detects that it has a deficiency, it will be able to ask its mechanical colleague to take over its tasks while it either troubleshoots and repairs itself or flags a human co-worker for service.

This futuristic scenario is quite similar to what is envisioned for self-driving cars. In the automotive world, technologies for vehicle-to-everything (V2X) communications could enable cars to communicate with each other, with traffic signals, and with other elements in the world around them. In the industrial environment, underlying technologies such as sensors, processors, power ICs, and advanced algorithms are paving the way for factory automation equipment to do the same.

Robots are already being used to facilitate fulfillment processes in warehouses. In the future, they may become even more self-sufficient. Photo courtesy of Chesky/Shutterstock

A Fresh Perspective on Industry 5.0

Meanwhile, some industry pundits have pointed to even closer collaboration between humans and increasingly more intelligent machines as a hallmark of Industry 5.0. But if this is the case, wouldn’t this be a step backward instead of the next phase of a technological evolution?

An engineer monitors factory robotics via real-time monitoring system software. Is this what Industry 5.0 will look like? Photo courtesy of Zapp2Photo/Shutterstock.

There’s room in the discussion for another perspective of Industry 5.0. In this view, as increasingly sophisticated artificial intelligence (AI) algorithms become commonplace, there is a potential to enhance machine-to-machine communications. For instance, if a machine in a factory cell becomes limited in its function, another machine in the cell can automatically take over to perform the stalled machine’s task while still supporting its own main task. This capability, or nimbleness, of the manufacturing line to keep it up and running will foster a new breed of underlying ICs that provide a higher level of flexibility to adapt its functionality to the requested task at hand. At Tesla’s Fremont production plant, human workers are currently alerted by flashing red and yellow lights when a particular robot needs maintenance. But in the future, we may see more automated factories where the robots require much less human intervention when one unit goes down for repairs. This self-aware digital factory approach does have implications on the human workforce, but, again, it’s a shift that began as Industry 4.0 matured.

Smaller and Smarter

While machines handle repetitive and physically taxing tasks, people would service or repair the machines…and design them. As AI algorithms evolve to become more accurate and reliable, this will influence the need for compact programmable logic controller (PLC) modules that provide universal IO capabilities to drive the industrial internet of things (IIoT) to the next level of dynamic control. One technology that provides facets of this universal IO capability is IO-Link. This powerful point-to-point serial communications technology provides flexibility to interchange sensors via a common physical interface, creating a number of software-defined sensors based on the IO Device Description file. The IO-Link port then serves as a universal IO that can turn into any type of sensor, so a factory worker can remotely reprogram these intelligent sensors to handle changed or new manufacturing requirements.

Pathways Toward the Self-Aware Digital Factory

For the past several years, Maxim has worked to create pathways for design engineers to realize their Industry 4.0 goals. At electronica 2014, the company demonstrated its Micro PLC platform, consisting of more than 75 ICs that work together to deliver 10x smaller size and more than 50% power savings compared to a typical PLC from that year. Two years later, Maxim brought to electronica 2016 the Pocket IO development platform, which enables design engineers to create, prototype, and fine-tune industrial control systems. The platform provides analog and digital I/O capability, motion control, and IO-Link intelligent sensor technology, reducing the PLC footprint to just under 10 cubic inches with a 30% power reduction compared to the previous platform. While Pocket IO continued the momentum of shrinking form factor, it also demonstrated a flexible manufacturing capability allowing dynamic, on-the-fly adjustment of the manufacturing line.

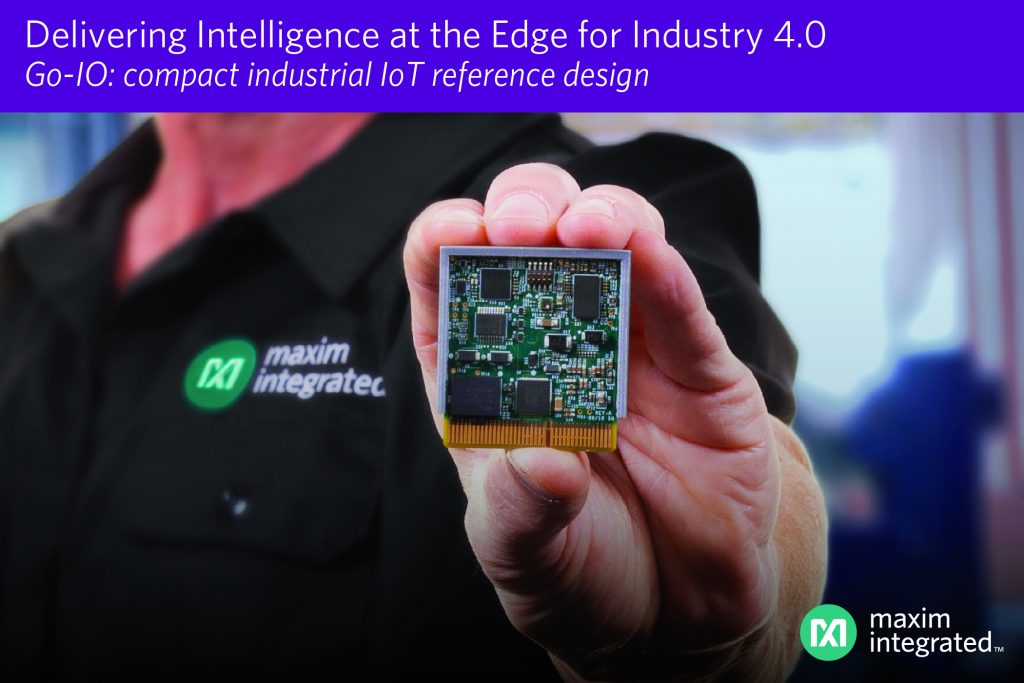

Then, at electronica 2018, Maxim offered another look at the latest technologies enabling the self-aware digital factory. The company demonstrated the Go-IO reference design (MAXREFDES212), which is a next-generation industrial IO solution that increases productivity, furthers adaptive manufacturing, and provides machine-level health and status information for making critical, real-time decisions. Go-IO, which packs 17 configurable IOs in a space one-half the size of a credit card, unleashes the full power of the IIoT, enabling productivity-enhancing self-diagnostic capabilities in automated factory subsystems, thus driving intelligence to the edge.

The Go-IO industrial IoT reference design drives intelligence to the edge.

As with autonomous cars, the deployment of autonomous robotics in industrial environments would need to be done in a measured way to ensure that the equipment can be trusted to make the right decisions. After all, it’s an inconvenience if a robot picks and packs the wrong item for a shipment. But the repercussions could be much more harmful if the wrong decision is made on, say, an oil rig or a nuclear power plant. The immediate challenge is to achieve a higher level of performance in which AI and decision-making are done in real-time at the edge of the manufacturing line, where equipment can be monitored and actions taken to improve environmental and human safety. Industry 5.0 promises to continue the efficiency and productivity momentum, while bringing human workers new opportunities behind the machines.