Image 1: A complete XEON 3

industrial computer with all the usual

peripherals on a single euroboard

of 3U and with only one slot space

requirement (4HP).

When the first electronic computer with its almost 17,500 tubes went into operation in 1946 with the ENIAC, the power loss of a good 175KW required special attention to the cooling of the system. If today, seventy years later, smartphones with their over 3 billion transistors and only about half a watt consumption are considered, the technical progress is impressive and cooling seems to be no longer an issue. But far from it: with increasing hunger for computing power in modern applications, the issue of lost power and waste heat is of new importance.

A typical industrial computer based on CompactPCI Serial with a 3U European card format generates a power loss of 50-80W in the form of waste heat with its XEON 3 processor. Such systems typically use high-performance graphics cards based on the NVIDIA GeForce GTX or the Quadro family, for the visualization of raw data, pre-processing and events. This adds up to 150W again. It is easy to network these systems via the built-in Ethernet interfaces or the CompactPCI Serial Backplane [1], thus further increasing the computing power. Systems with 5 or 8 CPU modules are easily possible without problems. Easily? Yes, if the high power loss of more than one kilowatt inside the volume of barely more than a shoebox would not overwhelm normal cooling systems.

One application for such computers is now to be found in the highly current topic “Autonomous Driving”. All manufacturers in the automotive industry are doing research on this subject and are on the roads with test vehicles. They capture relevant data from which they derive the insight as to which data and algorithms are required, and already partly react with these data autonomously (steering, braking, accelerating), albeit under the highly focused supervision of the test engineers and test drivers. These test systems are typically protected in the trunk of the vehicle, along with all other system and sensor electronics. This adds a further problem to the conventional exhaust air cooling of the multi-processor systems with high-performance fans:

Image 4: The entire waste heat of this video module is collected and transferred to

the upper end surface (bottom left in the picture)

It is not only a problem to remove the waste heat from the subframe, there is also the question of what to do with the heat inside the luggage compartment, in the immediate vicinity of the other devices. Inside the trunk, this would soon lead to massive problems in all test systems. A good impression of how full it can be in such a car trunk is gained through the pictures of the internet article “Piloted driving with the AUDI A7 Jack” published by the mobilegeeks.de website [2].

Image 5: Temperature inside the rack at several measurement points. T=0

Starting system w/o CoolConduct. At T=30 starting of the coolant pump. At

T=35 stable conditions.

These two problems are solved by the new system CoolConduct from EKF, which was developed to maturity in the spring of 2017 in cooperation with a German specialist of industrial liquid cooling systems. It consists of three coordinated components: A newly designed, 19″ compatible conductive plate is integrated above the subassembly of the subrack. A coolant is passed through the plate and is the primary heat exchanger for the components to be cooled. A unit with (redundant) cooling pumps and a coolant tank is connected to the subrack by two bayonet couplings, which can be placed several meters away from the subrack. The bayonet couplings are blow-back proof, i.e. they can be connected and decoupled in the field without coolant loss. The secondary cooling circuit is connected to the cooling pump with a further heat exchanger, which cools the coolant in the outside area. By means of these two circuits, the system can be used and cooled independently of the ambient air. Above all, there is no entry of dirt into the subassemblies via cooling. Back to our presented trunk workspace for our multiprocessor system: The primary heat exchanger cools the processor and graphics modules in the rack and transfers the heat via the medium to the secondary heat exchanger. This is mounted underneath the vehicle, transversely to the direction of travel, and transfers the heat to the environment, supported by the airflow. The entire system monitors itself, any errors are, of course, reported to the test system itself and processed.

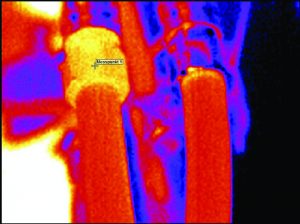

Image 6: In the thermographic image, the temperature difference in the cooling

tubes between primary and secondary heat exchangers can be seen very clearly.

Up to here, the system is certainly impressive by its robustness and thermal performance alone. However, the actual innovation patented is the way in which the modules are connected to the primary heat exchanger in the subrack. The current technology with so-called wedge locks, which was used primarily in the military sector, required specially designed and therefore expensive assemblies for this purpose, which required great effort to be kept up-to-date with the latest technology.

With the EKF technology, current computer assemblies (COTS) from the company-specific assembly program are used. The inverse, three-dimensional image of the assembly side is milled into a metal block and thus forms a form- and, above all, heat-tight connection, specific to this assembly, to the primary heat exchanger. These conductors are made of pure copper for optimum energy transport.

At the upper end of each such copper conductor is a planar surface, which is coupled to a special transfer module placed between the respective upper guide rails. These transfer modules are connected to the primary heat exchanger and have a high thermal efficiency and thus ensure the very efficient heat transfer.

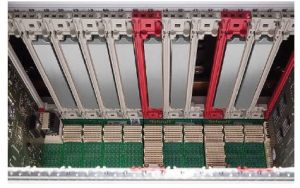

Image 7: Looking up at the heat transfer modules.

In the background, the CPCI serial bus backplane

can be seen.

As a result, the modules can be plugged into the subrack at any time in the field and can be easily removed for maintenance purposes, without the need for special tools and without having to disassemble the subrack.

This preserves one of the essential advantages of the 19 “technology, namely the easy module replacement in the field. Often, development teams of experimental software rely precisely on this possibility to change the software or the sensor system in the field, and to then continue with the experiment. Further applications are the expansion of CPU modules or the change of mass storage.

It is not only the high packing density and the small installation space of an industrial computer that can require a special management of the waste heat. There are many applications which require the cooling of computer systems separate from the ambient air, in order to prevent the penetration of e.g. explosive gases, dusts or oil-laden air. Such conditions of use can be found on drilling platforms as well as in opencast mining or in the paper-making industry, where sulfuric acid air pollutants [4] will often result in the creeping death of modern computers, since their solder joints contain an increased amount of silver, legally required by the changeover to lead-free solder (RoHS regulation).

Image 8: The careful encapsulation of

computer systems is unavoidable under such

environmental conditions

Further examples of high-performance computer clusters in a confined space can be found not only in the purely civilian sector. Current fields of work are armored, self-propelled vehicles for use in areas of conflict, simultaneous license plate tracking across multiple highway lanes as Homeland Security application, and face detection in hot, dusty environments. Another example that is both obvious and at the same time has an exotic ring to it, is automated, computer-assisted waste sorting. Conclusion

The CoolConduct system from EKF offers new possibilities for the test system planner as well as for the automator to allow for arbitrary computing power in his application. The advantages of high cooling performance even in harsh environments, the use of modern, up-to-date computer technology, and the ability to change the assemblies in the field is rounded off by another feature that is not expected considering the advantages: due to several intelligent details, the system is only half as expensive as traditional professional solutions available on the market.

[1]https://en.wikipedia.org/wiki/CompactPCI_Serial

[2]https://www.mobilegeeks.de/artikel/ein-selbstversuch-pilotiertes-fahren-mit-dem-audi-a7-jack/

[3]https://www.ekf.de/s/srs/srs8493/srs8493_pi.pdf

[4]https://www.dolge-systemtechnik.de/elektronik-korrosion