TOKYO– Toshiba Corporation (TOKYO: 6502) today announced the launch of “TB9044FNG”, a general-purpose system power IC with multiple outputs achieving functional safety[1] for automotive applications. Sample shipments start today, with the mass production scheduled to start in October, 2017.

More and more safety-critical automotive systems, such as electric power steering (EPS) and braking, are required to meet the requirements of ASIL-D[2], the highest automotive safety integrity level prescribed in the ISO 26262 functional safety standards.

The new IC integrates various failure detection functions, such as high-voltage and low-voltage detection and overheat detection of power supply circuit, to monitor against the IC’s own failure, and a watchdog timer to monitor failure detection of the external microcomputer. An initial diagnosis circuit to detect latent faults in the failure detection circuits is also incorporated to secure higher functional safety.

Toshiba has also carried out a range of functional safety analyses to simulate system failures and will provide customers with documentation, such as functional safety FMEDA[3], to support overall safety analysis and design.

Key Features

- Various built-in monitoring circuits for functional safety

-

- Low-voltage detection circuit for battery power supply

- High-voltage detection circuit for DC-DC converter (6V)

- High-voltage / low-voltage detection circuit for series power supply (5V)

- Overheat detection circuit

- Oscillator frequency monitoring circuit

- Watchdog timer circuit monitoring the external MCU

- Diagnostic circuit for failure detection circuits for functional safety

- A built-in diagnostic circuit in the failure-detection circuit detects any latent faults.

- Built-in buck-boost DC-DC converter

- The IC generates 6V output from a high efficiency buck-boost DC-DC converter.

In consideration of voltage drop after idling reduction, the low side operating voltage range is improved down to 2.7V (min.) with battery operation.

- Built-in 4 series power supply[4] circuits (4 outputs)

- The IC incorporates four series power supply circuits receiving the 6V input generated by the DC-DC converter.

It also incorporates a circuit with a 5V constant voltage (current capacity is 400mA) for the microcomputer, and three circuits with 5V constant voltage output (current capacity is 100mA) for sensors and other interfaces. Each of them can output a voltage independently.

- Selectable operation for failure detections

- Customers can set the system to respond to detected failures in one of two ways, using the SPI [5] communication input setting. One setting outputs a reset signal to the system; the other provides notification of the abnormal operation to the system. Selection can be made according to the customer’s application or system.

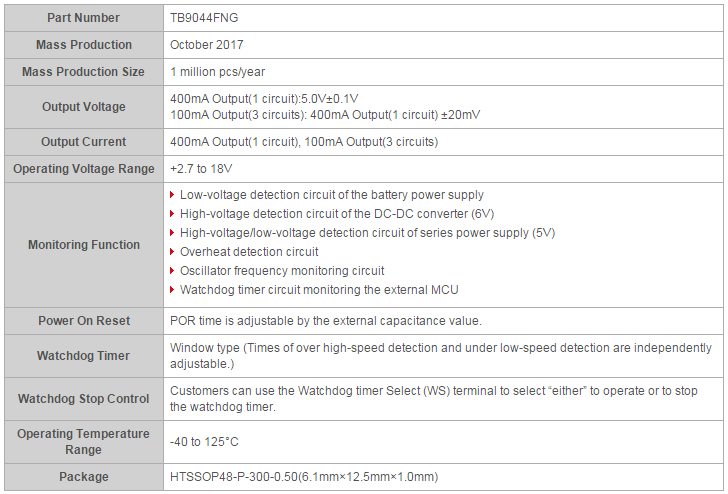

Main Specifications

Note2: ASIL: Automotive Safety Integrity Level

Note3: FMEDA:Failure Modes Effects and Diagnostics Analysis

Note4: Series power supply: The DC power supply circuit in which a voltage control element was connected to a load in series.

Note5: SPI:Serial Peripheral Interface