Vicor power-dense modules enable colossal telescopes to look into the past

Deep space exploration has captured the imagination for generations, driven by humanity’s desire to understand the origins of the Universe. It’s a journey of constant discovery and inspiration for Vicor’s Italy-based customer, Microgate, whose team of engineers invented motor control systems for massive earth-based telescopes using Vicor’s power solution.

Exploring deep space with the largest telescopes on Earth

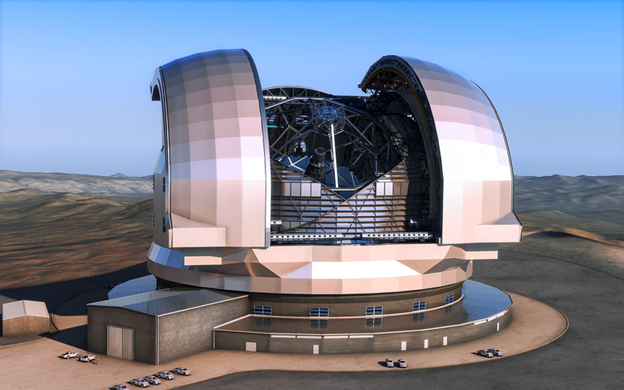

In a partnership with the European Southern Observatory (ESO), an intergovernmental research organization for ground-based astronomy, Microgate and ESO build the adaptive mirrors for the newest and largest generation of Extremely Large Telescopes (ELTs); which are ground zero for exploring new galaxies, stars and planets. The primary challenge of these telescopes is to capture light from the distant past to learn more about the origins of our Universe.

The new ESO-ELT houses a primary mirror with an impressive 39-meter diameter that collects the scarce photons available from distant stars and galaxies.

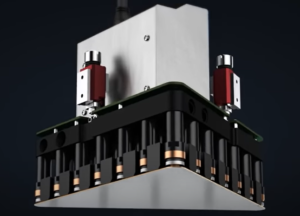

The secondary mirror is an adaptive mirror made of highly specialized glass with a thickness of about 1.9 millimeters. The copper-colored coils represent the linear motors.

The ESO-ELT M4 mirror is 2.4 meters in diameter and is made of highly specialized glass with a thickness of about 1.9 millimeters. The mirror uses voice coil-motors that are driven by a precise current driver and a series of co-located permanent magnets to provide the necessary force to deform the mirror. This process is performed across the entire surface of the mirror using 5,316 motors, each with an inter-axis distance, or pitch, of about 30 millimeters.

The adaptive mirror physically floats on the magnetic field generated by the motor coils. This allows a dedicated control current to locally deform the mirror and correct the shape using an equivalent number of highly-sensitive capacitive, or position sensors with an accuracy in the nanometer (millionth of a millimeter) range. Using electronic systems which operate at a frequency of about 100 kHz, Microgate engineers can completely redefine the shape of the mirror in one millisecond. The result is an extremely sharp and clean rendered image without having to launch a telescope into space.

Vicor power-dense modules power adaptive optics

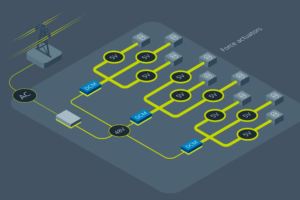

Precise manipulation and thermal management of the adaptive optics system is critical and requires all exposed surfaces to be kept close to ambient temperature to avoid local turbulence. The power system challenge is made even more difficult by the limited space.

Figure 3 Microgate uses the Vicor DCM3623 series DC-DC power module to mechanically deform the mirror and physically correct for these atmospheric disturbances. This process is essential to enhancing image quality.

Vicor’s DCM3623 series of DC-DC converter power modules was specifically selected by Microgate to power this process. The power system board is mounted on the underside of the gas-cooled cold plate, and each module powers up to 36 motor channels, eliminating complex wiring.

“Vicor’s high-efficiency and high-power density modules are very compact and reliable, and take up very little space on the circuit board,” said Gerald Angerer, Hardware Engineer, Microgate. “These miniaturized power converters are the best option for us. We have been using them for more than 10 years and there is currently no comparable substitute.”

Featured image: Microgate builds the highly sophisticated adaptive optics mirror for the ESO Extremely Large Telescope. The optics, powered by high-density DC-DC converter modules, correct for atmospheric disturbances to extract more light, achieving higher resolution imaging.