Recent trends in the defense industry show there is a convergence towards standardizing electronic systems using open standards to increase interoperability, scalability, reliability, reduce system costs, and minimize the number of custom electronics designs that increase overhead and maintenance. In 2019, a DoD Tri Services memo was published calling for a MOSA (Modular Open Systems Approach) to be used to the maximum extent possible for future weapon system modifications and new start development programs. The memo, titled “Modular Open Systems Approaches for our Weapon Systems is a Warfighting Imperative,” specifically cites the Sensor Open Systems Architecture (SOSA) Consortium, in addition to the Open Mission Systems/Universal Command and Control Interface (OMS/UCI), Future Airborne Capability Environment™ (FACE) and Vehicular Integration for C4ISR/EW Interoperability (VICTORY) standards, “as vital to our success.”

What does all this alphabet soup really mean? Are MOSA, SOSA, FACE, VICTORY, and others just more attempts by the government to provide the same framework for oversight within different groups? In peeling back the onion, the outcome is obvious. The government is trying to provide some guidance with respect to the tri-services (Army, Navy, and Air Force) involved in key weapons development. This MOSA memorandum really announced that there was a need to insure interoperability and commonality across key hardware and software development.

For many years prior, each of the service branches in cooperation with industry and academia, have undertaken development efforts that have led to many of the working groups including the establishment of OMS/UCI, SOSA, FACE, and VICTORY. These working groups and their efforts have all contributed to the MOSA initiative and driving commonality across future design efforts. Modularity and flexibility from both a manufacturing and design standpoint enables users to address thermal management considerations and provides adaptability where standards may deviate. Often times customers are trying to move the goalposts and push the boundaries of capability and performance; with a modular approach internally, this flexibility can often be achieved by substitution of one part of another to allow for a quick-turn deliverable.

SOSA and VPX power management

VPX (VITA 46) and OpenVPX (VITA 65) are two popular standards that are being adopted rapidly with VITA 62 providing the guidelines for developing a power supply to support both VPX architecture requirements. The modular power supply standard includes provisions for redundancy, scalability, and energy storage for systems that may require hold-up. While VITA62 is intended to support VPX applications, system designers can implement the modular power supply in applications that are non-VPX.

The VITA 62 standard provides guidelines for mechanical packaging, electrical and mechanical interfaces and communication specifications that a power supply can incorporate. Most common off-the-shelf VITA 62 compliant power supplies are equipped with six outputs:

- VS1 +12V,

- VS2 3.3V,

- VS3 5V,

- AUX1 -12V,

- AUX2 +3.3V and

- AUX3 +12V.

Outputs VS1, VS2, and VS3 are intended to be high current or high-power outputs while the auxiliary outputs are for low power and signal circuitry. VITA 62 power supplies can have different combinations of outputs on VS1, VS2 and VS3 to support VPX applications.

SOSA specifies a power supply with fewer outputs than VITA 62 while heavily referencing VITA 62, VITA 46, VITA 48, VITA 65, and various MIL-STD standards for design guidelines and power and electromagnetic compliance (EMC).

SOSA aligned power supplies only have two outputs – VS1 12V and VAUX 3.3V. The VITA 62 standard also defines standard control logic both analog and digital for operating the power supply, which increases interoperability and reduces designer’s burden for implementation.

Both SOSA aligned and VITA 62 power supplies can be equipped with two independent I2C communication channels. An optional communication interface is defined in VITA 46.11 utilizing the intelligent power management interface (IPMI 2.0) commonly used in autonomous computer systems that provides management and control of the power supply.

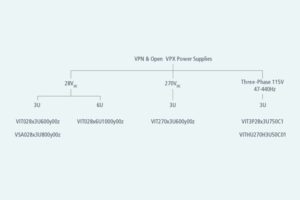

Power supplies designed around VITA 62 and SOSA have multiple input AC and DC input options with a fixed number of outputs. The classes of power supplies offered by VICOR to support open architectures are categorized by their input voltage.

All power supplies defined by the VITA 62 and SOSA standards have at least two alignment key slots based on their input power characteristics. A 3U power supply with a 16V to 50VDC input cannot be inserted into an application that requires 3U single-phase AC power when the system designer implements keying defined by Tables 4.3.2in VITA 62.0.

Deployment of any new power solution in a defense application requires meeting various environmental and electrical MIL-STD standard specifications before adoption. VITA 62 compliant power supplies can optionally meet EMC compliance defined in MIL-STDs 1275, 704, and 461, listed in Section 3.2 of VITA 62.0. Testing power supplies in systems can be a multi-month process requiring iterations to the design of the power supply, EMI filtering or system back plane to pass required EMC standards. VITA 62 and aligned power supplies stand out in the market by guaranteeing all power supply models comply with the standards listed in their datasheets and are verified at independent certified test labs.

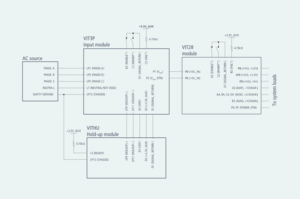

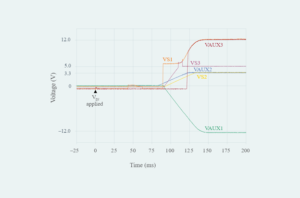

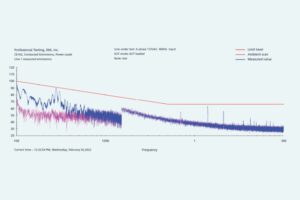

Figure 3a shows a typical VPX power supply two-stage application where stage 1 is a Vicor front-end three-phase AC input module VIT3P28M3U750C coupled with a Vicor energy storage VITHU270H3U50C01 hold-up card to provide 50ms hold up at full power. The first stage provides a single 28V output and is connected to the second stage, a back-end Vicor VITA 62 VIT028T3U600C000 supply where the outputs are loaded at 600W in aggregate. Calibrated test lab EMI scans in Figure 3b show the entire system passing MIL-STD-461G CE102 EMI scans.

Figure 3b: MIL-STD-461G CE102 EMC Scan of a three-phase input line when the outputs of the VIT028x3U unit are loaded at 100%. Credit: VICOR

Scalability of power solutions is a cornerstone of open systems architecture standards. To this end, VITA 62 and SOSA standards provide recommendations for power supplies to be paralleled to combine the output capability of their main outputs. Design standards reserve contacts on the connector interface of the power supply to simplify paralleling power supplies and balance their output current sharing.

Paralleling can be taken a step further by unloading the burden of paralleling from the system architect by facilitating current sharing between supplies without the need for reserved contacts that are dedicated for power sharing between supplies. Conventional VPX power supplies require careful system design and special power supply part numbers to enable current sharing between supplies.

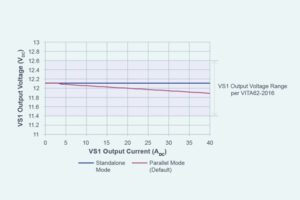

Current sharing between power supplies from Vicor have a proven wireless droop sharing algorithm. Figure 4 shows how the VS1 +12V output of a 6U power supply operating in paralleling mode. The output voltage varies with load current while still maintaining its voltage within the VITA 62 limits. The company’s power supplies have been tested with as many as four units operating in parallel for current sharing.

If the system designer only requires a single power supply in their application, the power supply can be reconfigured through its I2C communication interface on the fly to disable droop sharing, thus achieving better than 1% output tolerance with under variable load (See standalone operation of VIT028x3U600y000).

Figure 5: A stack of four VIT028x6U power supplies for system output power capability by 360% compared to a single unit. Credit: VICOR

I2C communication with SOSA-aligned and VITA 62 power supplies are defined by the VITA 46.11 standard. Conventionally, a 3U power supply supports four addresses, which are set by the application by pulling address pins to logic high or logic low. 6U power supplies support five addressing pins and a wider range of possible I2C address assignments. In a single VITA 62 power supply application, the system designer can now ignore (no connect) the I2C pins, and communicate with the single power supply on address 0x20.

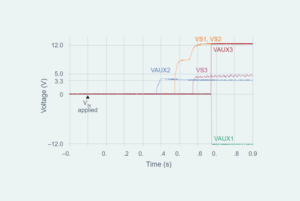

Another advantage in deploying a modular power supply in an application is the ability to have fast start up times by default or customizable start up times and sequencing. In single-stage back-end power supply applications, the power supplies are capable of 200ms start up on all outputs for applications that require it.

VITA 62 and SOSA aligned power supplies are designed to be able modifiable at the factory to vary the output voltage as well have different output voltage combinations that are not part of the standard offering for a variety of applications. By using a modular approach internal to the packaging, the user can easily provide changes to output voltages or power levels in usually short order.