Until recently, very few companies could manufacture flexible printed circuits (FPCs) of more than a couple of metres in length. However, new manufacturing techniques now enable the design and production of multilayer FPCs of unlimited length. This is opening up a world of new applications that previously had to be served using conventional and bulky wire harnesses.

From a concept first postulated by inventor Albert Hanson in patents of 1902 and 1903, FPCs now represent a multi-billion dollar, global market. Incidentally, the term ‘printed circuit’ is a little misleading because FPCs, like their rigid counterparts, are manufactured using a subtractive process whereby copper is chemically etched from its substrate to leave the conductive circuit elements. It’s not printed onto the substrate, so FPCs should not be confused with recent innovations in ‘printed electronics’.

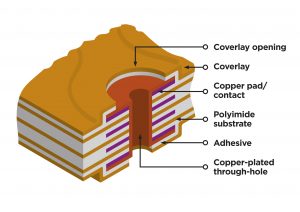

Substrates are made from a variety of materials. Polyesters and polyimides have been popular, but other advanced polymers are now emerging, particularly thermoplastic versions which can be laminated onto fabric or operate at very high temperatures.

FPCs may be single- or double-sided, or, for higher density interconnects, multilayer. Multilayer FPCs are typically formed from several single- or double-sided flexible circuits bonded together with conductive and insulating layers and plated through to form a compound interconnected device.

In the application, flexible circuits may be static or dynamic. They can be ‘flexed-to-fit’ into the required housing, enabling complex circuitry to be embedded in curved and aerodynamic structures. Alternatively, in a dynamic design a circuit may be flexed in operation, such as connecting through a hinged assembly like a car door hinge.

A single FPC can replace not only ribbon cable, discrete wiring or complex wiring harnesses, but also connectors and even conventional, rigid printed circuit boards (PCBs). FPCs save weight and space, and often reduce costs while improving circuit performance. What’s more, taking advantage of the 3D nature of FPC technology, circuits can be folded and shaped to fit specific form factors, which might be impossible to do with conventional PCBs and cables.

Figure 2: Flexible circuits can replace complex wiring looms and be fitted neatly into or around car components, such as headlights or door frames.

FPCs are found across the spectrum of electronic and electrical products: automotive, consumer, medical, entertainment, IT and industrial equipment. They are used widely in hand-held devices such as electronic games consoles, laptops, smartphones and cameras. Chest straps and wrist bands for sports and health monitoring devices are obvious wearable application examples. But they are also used in tiny devices such as hearing aids, heart pacemakers and medical pumps. Ultra-thin, flexible substrates have also enabled skin patches for monitoring blood sugar or for dispensing medication. In industry, smart labels incorporate RFID tag circuitry for security, anti-counterfeiting and transport logistics/tracking.

A summary of the benefits of FPCs

- Space saving: very thin dielectric substrates, some down to 25µm or less, coupled with their planarity, make it possible to bond the circuits to, or within, the structure of a product.

- Weight saving: the corresponding reduction in weight is amplified as fewer connectors and fixings are required. Smaller conductors and reduced copper content make an additional contribution.

- Versatility: FPCs are custom-designed to fold, bend and fit into virtually any shaped housing.

- Ruggedness: robust connections compared to wire harnesses as the flat foil conductors within the FPC can dissipate heat better and carry more current than equivalent round wires. Fewer interface connections increase reliability. Physically more resistant than rigid PCBs to vibration and shock.

- Higher operating temperature: thermal stability is better, particularly with polyimide materials, allowing the circuit to withstand more extremes of heat than rigid PCBs. Thermal mismatch is also reduced.

- Crosstalk and noise: these are more easily controlled using a uniform conductor pattern in the flex circuit. Ground plane options include lightweight cross-hatched, solid copper, aluminium or lightweight shielding films. Stitching vias and internal guard rails can provide 360o shielding, with plated vias along the length of the circuit.

- Good EMC performance: reduced radiated emissions due to the smaller ground loop created by the guard traces, and better differential-mode transmission loss characteristics.

- In data bus applications, better-controlled impedance characteristics, reduced transmission loss and lower radiated field emissions due to shorter current return paths.

- Simpler, more reliable installation: faster assembly of fewer component parts; improved repeatability as less manual intervention; no need to colour code wiring. Resulting in lower installation costs, reduced risk of rejects during assembly and fewer in-service failures.

The IHT manufacturing process and the new applications it enables

As mentioned earlier, the length of multilayer FPCs that can physically be manufactured has restricted their adoption in many applications. Length has been limited typically to 610mm, although there are a few manufacturers capable of producing circuits a few metres long.

A patented process known as Improved Harness Technology™ (IHT) is now overcoming these limitations. IHT is a roll-to-roll manufacturing process which not only enables the manufacture of multilayer FPCs of any length, but also, being machine intensive, makes it cost effective.

In conventional FPC manufacturing, process steps including drilling, imaging, pressing and plating, are based on equipment that typically uses static processes. IHT uses specially adapted machinery and custom software to enable the dynamic processes required to manufacture FPCs of indeterminate length. Additionally, the IHT processes use materials in roll form, as opposed to the fixed size sheets which most materials are supplied in.

Careful analysis and planning is required before embarking on any FPC implementation project. When specifying requirements, the customer must liaise closely with the manufacturer to ensure that an FPC is actually suitable for the application. Also, in order to ensure that the end product performs as intended, a detailed design process should be followed, covering the end product requirements, the intended operating environment, package configuration, mechanical and electrical characteristics and assembly method. The output from this process will provide the specification required by the FPC manufacturer in order to validate the design and provide relevant quotations.

With IHT, Trackwise is primarily targeting the replacement of conventional wire harnesses, where assembled components are limited to connectors. The long FPCs produced by the IHT process are however, essentially PCBs and can be populated with components, using either PTH or SMT techniques so as to produce a ‘smart’ harness.

Today, the automotive, aerospace and telecommunications industries are increasingly reaping the benefits of FPCs. Replacing large, heavy and complex wire harnesses, flexible circuits are now used to meet the space and weight constraints of the growing number of in-cabin and on-board systems.

In cars, for example, electronically-controlled features have increased exponentially in recent years. There can be from 30 to 100 electronic control units in today’s vehicles, covering every aspect from engine management, passive and active safety, and passenger comfort. Luxury models can contain up to 1,500 copper wires, totalling a mile or more in length, which all need to be interconnected. The percentage will only rise with the influx of electric and autonomous vehicles.

The civil aerospace sector follows much the same trends. In any aircraft, saving weight is particularly crucial as it affects operating costs and emissions.

IHT makes it possible to create a single flexible circuit structure that can span aircraft wings or reach from nose to tail. Important sub-system and system level benefits are gained, as the FPC becomes a subsystem itself. IHT may also enable distributed electronics, including sensing and signal conditioning functionality, to be integrated into the circuit. This effectively creates a smart interconnect, entirely replacing passive wire harness interconnects.

In aerospace applications, flexible circuits have been shown to reduce weight by up to 75% over traditional wire harnesses.

One recent application of IHT involves a 10m long, 6-layer, arc-tracking compliant harness for a commercial airliner. Other aerospace projects include a 42m multilayer circuit for a power transfer harness for a roll-out solar array for spacecraft and a 26m long shielded FPC for transferring power and signals across the wingspan of an unmanned aerial vehicle (UAV).

Electric vehicle applications are beginning to emerge too, where FPCs produced using the IHT process are expected to be adopted in high- and low-voltage harnesses for electric vehicle battery packs. Here, the FPC may combine power, control and monitoring circuits.

Conclusion

With the trend towards sustainability and protecting the environment, there are many new developments to come in the automotive and aerospace markets. Future projects include electric vehicles, UAVs, more efficient aircraft engines and satellite technology. These, and others, in the medical and industrial arena will benefit from the design and manufacture of flexible circuits of unlimited length.