Since its introduction in 1980 and standardization in 1983 as IEEE 802.3, Ethernet allows computers to connect to other computers, servers, printers, scanners and other peripherals over single networks. These often use numerous switches that connect computers, printers and other wired devices to each other and are often wired to routers and models to allow Internet access. In office settings, especially, Ethernet is now the most popular and widely used network technology in the world with millions of computers and peripherals linked together with the standard.

Like every other networking and interface standard, Ethernet has evolved from supporting data rates over ranging from the now obsolete 10BASE5 (10 Mbits/s), through 1000BASE-T (1 Gbits/s), and 10GBASE-T (10 Gbits/s). Newly introduced data rates over twisted pair now include 25GBASE-T (25 Gbits/s) and 40GBASE-T (40 Gbits/s), part of the IEEE 802.3bq standard. In 2016, recognizing the need to develop a lower power, more cost-effective version of 10GBASE-T (10 Gbits/s) over twisted pair networks, the IEEE standards board ratified the 802.3bz standard which encompass 2.5GBASE-T and 5GBASE-T.

A Balancing Act

While 2.5GBASE-T specifies speeds of up to 2.5 Gbits/s and operating at distances to 100m over CAT 5e cable, the 5GBASE-T can operate as fast as 5Gbit/s at distances of 100m over CAT 6 cable. Although 10GBASE-T operates at 10Gbits/s and can be used for camera to computer distances of 55m (using CAT 6 cable) and 100m (using CAT 6A cable), Power over 10GBASE-T is not currently supported although it has been proven to work theoretically. In addition, 2.5GBASE-T and 5GBASE-T allow system designers to forgo costly re-cabling of existing Ethernet solutions since the vast majority of installed Ethernet cabling is already CAT 5e and CAT 6 . Thus, the use of existing cabling combined with the lower power consumption and Power over Ethernet (PoE) has made 2.5GBASE-T and especially 5GBASE-T an attractive alternative, striking the right balance between speed, distance and costs not just for communication systems, but also for manufacturers of machine vision peripherals such as CMOS-based cameras.

When compared with the fastest Camera Link Extended Full or Deca version that runs at a maximum of 6.8 Gbit/s over a maximum distance of 5m the benefits of a 5GBASE-T interface not requiring an expensive PC-based frame grabber or custom cabling also becomes apparent.

Fast Running 5GBASE-T Cameras

Recognizing these benefits, a number of companies have now introduced both line scan and area array-based cameras based on the 5GBASE-T standard. One example of such an area array camera is LUCID’s Atlas ATL314S 5GBASE-T camera featuring the large format 31.4MP IMX342 CMOS sensor from Sony. With an M12 Ethernet connector capable of transferring up to 25.50 w (PoE+, Type 2) and 5Gbit/s of data, the camera can operate at a resolution of 6464 x 4852 with frame transfer rates of 17 fps at distances of 100m over CAT 6 cable.

Figure 1: 10GBASE-T has a Nyquist frequency of 400 MHz, i.e. most transmitted data is contained below this frequency. Reducing the speed to 5 Gbps (5GBASE-T) reduces the Nyquist frequency to 200 MHz, thus falling within Category 6 cable’s specified bandwidth. Reducing the speed to 2.5 Gbps (2.5GBASE-T) reduces the Nyquist again by half to 100 MHz, within the specified bandwidth of Category 5e cable.

Not Just About Speed

There are many reasons why manufacturers of machine vision cameras have embraced the 5GBASE-T standard. Just as Camera Link Extended Full version runs at a maximum of 6.8 Gbits/s over distances of 5m, the USB 3.1 and USB 3.2 interfaces (although they can transfer data at up to 10 Gbits/s and 20 Gbits/s respectively) are limited to camera-to-computer connection distances of 5m (USB 3.1) and 3m (USB 3.2). Similarly, the fastest camera-to-computer interface, CoaXPress (CXP) can transfer data at speeds as high as 12.5 Gbits/s per CXP link, and thus 50 Gbits/s using four links. Cable length is limited to a maximum of 35m at these data rates; however, if using slower data links of 3.125 Gbits/s, cables can be extended to 100m.

Like Camera Link, a relatively expensive (+$2500) PCIe frame grabber is required to implement CXP-based systems. Some high-speed line-scan applications (such as web inspection) demand low latency, low-jitter, point-to-point interfaces, therefore CXP systems must be deployed.

In other, less demanding machine vision applications, 5GBASE-T is a more cost-effective solution (Table 1 below). For ranges of line-scan and area array cameras, vendors offer support for GigE Vision, an interface standard developed in 2006 by a consortium of mainly camera companies and now administered by the Automated Imaging Association (AIA).

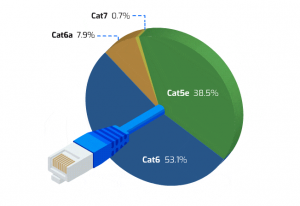

figure 2: : Examining the installed Ethernet outlets by cable type shows that currently CAT 5e and CAT 6 cabling dominates the market while CAT 6a and CAT 7 cabling is only just starting to emerge to support higher data rates. The low-cost CAT 6 cable is one reason why camera vendors have adopted 5GBASE-T, a standard that operates at 5Gbits/s at distances of 100m over CAT 6 cable.

Embracing GigE Vision and GenICam

GigE Vision provides a framework for transmitting high-speed video and related control data over Ethernet networks, making it easier for developers to build software. As part of the standard, GigE Vision’s GigE Device Discovery Mechanism provides mechanisms to obtain IP addresses and an XML description file that allows access to camera controls and image streams that is based on the GeniCam standard developed by the Verband Deutscher Maschinen- und Anlagenbau (VDMA; Frankfurt am Main, Germany).

While GenICam exposes features of a camera (such as frame rate) through a unified API and GUI, each feature is defined in an abstract manner by its name, interface type, unit of measurement and behaviour. The GenApi module of the GenICam standard defines how to write a camera description file that describes the features of a device, how to be interoperable, and uses the GenICam Standard Features Naming Convention (SFNC) providing a common set of camera features, their names, and their behavior.

The Importance of Being on Time

While GigE Vision and GenICam standards allow for different devices to work with each over Ethernet the issue of deterministic behaviour between devices still needs to be addressed. Business systems and office environments using Ethernet do not require precise or critical timing between devices to function properly, because it is not crucial if all data packets are correctly sent and received, or whether they are sent and received during a known period of time. However, for industrial Ethernet systems such as a machine vision system inspecting parts in a timely fashion, determinism is required. Industrial systems must be highly deterministic because any failure to transmit, receive, or act on processed data at specific times can result in data loss and delays producing an unpredictable industrial system. Determinism is therefore highly important and has been addressed by a number of specialized industrial Ethernet protocols.

Figure 3: Atlas 5Gige Camera – The Atlas camera with Sony Pregius Sensors over 5GBASE-T PoE. GigE Vision and GenICam compliant camera capable of 600MB/s data transfer rates (5Gps), allowing for high resolution and high frame rate over standard copper ethernet cables up to 100m.

Deterministic Ethernet Protocols

Popular industrial Ethernet protocols include PROFINET, EtherNet/IP, EtherCAT, SERCOS III, and POWERLINK. Since there are major differences in the technical approaches taken by each of these protocols, supporting every one of them would be a Herculean software effort for all but the largest manufacturers of industrial automation equipment. Each protocol offers real-time and deterministic behavior for devices and each has various supporting companies and manufacturers. However, EtherCAT is the most adopted and offers both superior performance and market acceptance, delivering real-time, deterministic responses required by industrial machine controllers using low-cost network interface cards (NICs) and Ethernet cables. (2)

To support this collection of protocols, also referred to as a fieldbus, the OPC Unified Architecture (OPC UA – IEC 62451), an open standard developed by the OPC Foundation, can be used to specify the information exchange for industrial communication on computer-based machines, in-between machines, and from machines to and from computers systems.

With OPC UA, developers can take advantage of OPC’s data model and services that enable devices to exchange data with an agreed and shared meaning, rather than mapping data as byte streams. At the same time, the EtherCAT Technology Group (ETG, Nuremberg, Germany) and the OPC Foundation’s technologies complement each other with EtherCAT being used as a real-time-Ethernet fieldbus for machine and plant controls and OPC UA as a platform for scalable communication.

Making Machine Vision Systems

While the collaborations above are useful, they do not specifically address the needs of developers of machine vision systems wishing to leverage Ethernet-based systems on the factory floor. To do so, the VDMA has collaborated with the OPC Foundation to form an OPC Vision Initiative to develop an OPC UA companion specification for machine vision (see “OPC UA Vision,VDMA Specification”, Draft Version November 2018(

While the OPC UA describes data, functions, and services of embedded devices, machines and data transport for data modelling, OPC Vision allows industry-specific definitions of products such as cameras to be defined, similar to the GenICam Standard’s Features Naming Convention. As well, the OPC Vision Interface can be integrated with fieldbus standards such as EtherCAT to form a complete system model for real-time deterministic systems that can be integrated with OT production control and IT systems.

With the emergence of the OPC Unified Architecture (OPC UA), the OPC Vision Initiative and the IEEE 802.1, standards for time-sensitive networking (TSN) companies can use a single Ethernet network for both time-critical, deterministic applications such as image capture and less time-critical IT systems. Since the OPC UA TSN standard can be applied to computer-based nodes on the network, including cameras, PCs, PLCs, and server-based systems, it will be especially useful in developing edge-based and cloud-based network applications.

5GBASE-T: The Sweet Spot

5GBASE-T cameras coupled with standard Cat 6 cables allows cameras to be easily located at up to 100m from the host computer in a variety of flexible network topologies. Eliminating the need for relatively expensive frame grabbers also lowers the overall system cost while still allowing 5Gbits/s image data transfer from the camera, fast enough to address a broad range of vision applications. When established, efforts such as the OPC Unified Architecture (OPC UA) and the OPC Vision Initiative will ease the deployment of 5GBASE-T cameras in industrial fieldbus-based Ethernet networks, simplifying the task of systems integration. These aspects combine to build a balanced interface offering flexibility, bandwidth, low cost, and strong reliability for high speed vision systems.