This article will provide an introduction to, and overview of, the subject of embedded motion control and some considerations for design engineers when implementing motion control in embedded systems. Embedded motion control is a major emerging trend that’s being driven by the interconnectedness of many different systems, such as new edge device applications in the Internet of Things (IoT) and the industrial IoT (IIoT), as well as other trends such as increasing integration and miniaturization of systems, and the spread of mobile/wearable consumer electronics – and artificial intelligence (AI).

What’s Driving the Emergence of Embedded Motion Control?

Several different trends, both application related and user (engineering) related, are working together to spur the increase in embedded motion control. Even before the recent emergence of IoT and IIoT edge devices, many of these trends were already occurring.

Figure 1: Miniaturized PCB custom-made for a perfect fit in Össur’s Power Knee, a battery-powered prosthetic leg.

(Application related) Simultaneous increasing miniaturization/integration and automation: One of the most important trends, and one that influences so many others, is the increasing miniaturization and integration of systems, components, and assemblies, at the same time they are also being automated. This is also true in new miniature motor types with very small form-factors, for example Faulhaber PRECIstep stepper motors. Demand for stepper motors overall continues to rise, due in part to a rise in demand for miniature motors, according to a report by P&M Market Research reports. Although industrial machinery has been the largest market segment for stepper motors, said this report, their rising use in medical equipment, desktop manufacturing, or home automation will drive market growth by 2023.

Electromechanical actuators are getting smaller and so is the available space for some kind of driver stage or embedded electronics. At the same time, what could be implemented before only in large microcontrollers (MCUs) can now be done in small, smart, highly integrated solutions. Engineers are looking for the most amount of integration, both functionally and physically, in the smallest possible space. This is true of both silicon and product packaging, as more engineers make use of systems-on-chip (SoCs), and system-in-package (SiP) configurations paired with a small-outline printed-circuit board (PCB).

(Application related) New applications enabled by miniaturization/ integration: Increasing miniaturization and integration, and increasing automation, are already occurring in what have been the typical application areas for motion control: industrial automation, robotics, laboratory automation, and medical equipment systems.

The miniaturization/integration trend is also enabling many new mobile, wearable, and other lightweight systems in medical and consumer-side applications. Design needs here are driven by mobility, battery power, and connectivity, which require small devices, in addition to the building block approach to motion control design. A good example is smartphones: years ago they had lots of dedicated voice and graphics processors, and a general processor for the operating system. Today, these have all been integrated into a single processor.

Other applications being enabled by this trend include 3D printing, and IoT-connected devices for consumers. This latter group includes connected home devices such as window shades, blinds, and cameras for smart home systems; environmental controls such as connected thermostats; appliances; robots; drones; automotive; and consumer devices that require stepper motors. For wearables, some examples are small portable insulin pumps containing small stepper motors, which also need a wired or wireless interface and are battery driven, and virtual reality goggles.

(Application related) Growing interconnectedness fostered by the IIoT: Networks are growing. Bandwidth is growing. The amount of information exchanged over all networks, including over the Internet, is growing. Global semiconductor and technology companies are placing their highest focus on solutions for networking, for data centers, and high-bandwidth communication technologies – in global telecommunication and media, in industrial control applications, as well as in automotive and home networks.

To keep pace with this development requires more intelligent systems, including motion control and drive solutions at the network edge with standardized APIs and standard interfaces so these systems can understand and communicate with each other.

(Application related) AI: Artificial intelligence is a trend on the algorithm side, in software and dedicated hardware, and it is a radical change. AI allows for intelligent and autonomous machines, it allows for systems that make decisions based on their available “information” without human control, it allows for learning/adaptive machines, and it allows for interactive machines. Because of AI, new application areas are emerging which will become commodities in a few years, such as advanced robotics in factories and in medical applications, the transportation & delivery industry, or toys. Nevertheless, to actually interact with the real, physical world – transforming digital information into physical motion and vice versa – AI-based systems require smart actuators. Such smart actuators are examples of embedded motion control systems.

(User/engineer related) Software-centric engineering: At the same time, a different trend is also making standardized APIs and interfaces a must. TRINAMIC Motion Control is seeing a new generation of engineers focused more on software and applications than on the hardware design of motion control and motor control. Because more and more engineers are not familiar with the physics of motion control and motors, or an understanding of mechanical and materials challenges, standardized interfaces and APIs have become increasingly important. These engineers want to work with interfaces, not motors, so they expect motion control solutions that incorporate these and are ready to use. This trend is raising the abstraction level needed in the products engineers use for development, which in turn makes the building block approach to motion control a necessity.

Figure 2: All control and communication embedded in KUKA’s YouBot is taken care of by Trinamic, freeing KUKA’s engineering teams from motion control so that they can focus on their core expertise instead.

(User/engineer related) Hiding complexity: Two different drivers are helping engineers develop systems without having to deal with all the complexity of these new small systems with their multiple sensors, algorithms, and interfaces. In addition to the increase in embedded motion control, which hides the complexity of interfaces by providing them out of the box, many design components are becoming commodity and off-the-shelf. What has been exclusive before is now standard, in what design engineers expect from a drive or a chip. Yet these still have the same complexity, which is why no one wants to implement these functions all over again, so they must be made available as building blocks.

What Exactly Is Embedded Motion Control?

Embedded motion control not only means using an embedded system for motion control tasks or implementing the motor and motion control functions in highly integrated microchips. Embedded motion control means more than just motor control. It means the whole motion control system in miniature. So what does this mean in detail?

It’s about communication and synchronization: This means communication with higher-level control entities in IoT/IIoT environments, with multiple actuators and sensors, but also synchronization across multiple systems or in multi-axis application scenarios. Engineers must consider not only a motor and how to use it in the application, but also how the actuators connect to and interact with all the other building blocks in a real, physical system.

It’s about abstraction and ease-of-use: This means embedding motion control tasks and related functions in a complete, out-of-the-box subsystem that puts together electronics, software, interfaces, motors, and sensors. Motion control has become a building block. Engineers want this and need this. The reasons are challenging time-to-market requirements and the need to focus on the actual application layer instead of “standard” or “base” functions.

It’s about the mechanical side: motion and motor control are always related to mechanics, rugged or harsh environments, and various physical constraints. With increasing miniaturization, space is also limited or requires custom outlines. Designing embedded motion control systems always starts on the mechanical side — this is key.

To summarize the typical attributes of embedded motion control systems:

They combine different blocks that had previously been separate: control/bus interface, application software, sensors, actuators, and some piece of “intelligence.”

They hide complexity by encapsulating sophisticated algorithms and functions – or even just common state-of-the-art functions.

They can “talk” using a standardized protocol and offer an API. Thus, they offer an excellent software interface, which is welcome in AI applications for example.

They can do more than just spin a motor: they can also evaluate sensors, preprocess data, act mostly autonomously, and offer safety & monitoring functions and diagnosis.

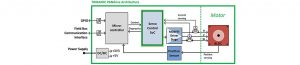

Figure 3: Top-level block diagram of the TMC8670 shows the different blocks that are all combined in one single motor driver chip, such as communication and FOC in hardware.

Embedded motion control solves mechanical challenges.

Embedded motion control systems transfer digital information into physical motion.

Considerations for Implementing Embedded Motion Control

What makes embedded motion control so attractive to today’s design engineers? It’s cheaper, available off-the-shelf in ready-to-use building-block form so it saves development time, and includes standard interface protocols.

The lower cost of embedded motion control comes from shorter time-to-market, reduced overhead cost of firmware development and updates, and reduced BOM cost. These three advantages are especially important in certain application areas, such as consumer electronics.

In connected IoT/IIoT-related applications, since they are small and often mobile, energy efficiency and noise control are at least as important as cost, and can be major design challenges:

Energy efficiency: low voltage, (sensorless) field-oriented control, offloaded processor

Noise cancellation: microstepping, current control, and voltage control for smooth, precise, and ultimately silent motion.

There are several overall considerations when making the decision of whether to implement embedded motion control. Design engineers should ask themselves:

What’s my sweet spot in terms of cost?

Am I an expert in motion control or not?

Can I/do I want to do it on my own?

How much time for developing my application can I eliminate?

Trinamic has addressed several of these themes in two white papers: “How motion control defines system design — The engineering view” and “Build vs Buy: Why Developing Your Motor Driver with Smart Microsystems May Be Your Best Option.”

While all of these are key questions, time-to-market is an ever-increasing factor and development times are shrinking rapidly. In fact, engineers at Trinamic are affected by this, too, during our own internal design process. For example, several new customers for custom projects have said they need to get a board working in only two weeks. So it’s important to keep in mind that, while some engineers might want to design everything themselves, that may take too long for today’s reduced product development cycles.

Conclusion: Examples of Embedded Motion Control

The design of motion control is no longer difficult or complicated: instead, it has become a set of mainstream functions, or building blocks, which can help designers reduce their development overhead. We can now embed functions and sub-blocks physically (motor, sensors, housing, physical interface) and logically (algorithms, communication stacks, dedicated hardware accelerators), combined according to an engineer’s specific application needs.

Examples of increasing integration and miniaturization can be found in Trinamic’s smart stepper controller + driver IC family, such as the TMC5130 / TMC5160 integrated motor driver and motion controller IC. The TMC5072 can even drive two motors directly out of the IC. The TMC8670 dedicated EtherCAT motion controller IC is an example of the highest levels of integration. It’s an SoC with a field-programmable gate array (FPGA) and a real MCU inside, and includes EtherCAT real-time bus interfaces, protocol stacks, plus servo motor control in a single device.

Another example of integration and miniaturization is Trinamic’s TMC4671, a fully integrated servo controller with integrated analog-to-digital converters (ADCs), position sensor interfaces, and position sensor interpolators, and the PANdrive products, which are complete drive systems, including motor, ready to be used out of the box.

If you think about all of these trends like AI, IoT, and IIoT, it becomes clear that they are typically located more on the processing and communication side. Nevertheless, many systems need a bridge to the real world. When people think about the IoT, they think sensors and data (the cloud). However, it’s the actuators that give meaning to the IoT and make life comfortable by enabling the physical cloud, which consists of all the physical devices connected to the Internet. Embedded motion control is this bridge that connects the digital to the physical.