Introduction

Rapid growth in the number of connected devices for next generation wireless applications is driving demand for faster, more innovative, and more cost-effective test solutions. The need for reduction in cost and improvement in test throughput is found both at the design verification stage as well as in high-volume production testing. Test engineers are looking for ways to reduce the number of device-under-test (DUT) connections and enable testing of multiple DUTs in parallel from a single test station. This is most often achieved by configuring RF switches in a switch matrix to automate the routing of test signals. This article will explore some of the key differences between the types of switches used in test applications. Switch matrix configurations will be discussed, and a real world switch matrix for a high-volume telecom test application described in detail.

Key Design Distinctions between Solid State and Mechanical Switches

RF switches fall into two basic design categories: electro-mechanical and solid state (Figure 1). Some of the key performance parameters of RF switches for test applications include isolation, insertion loss, power handling, switching time, and switch life. Mechanical switches tend to support higher power, have lower loss, and better isolation. However, they have slower switching times, are larger in size, and their repeatability begins to degrade after several million switching cycles.

Figure 1. SP8T electromechanical switch, MSP8T-12D+ (left), and dual SPDT solid state switch, USB-2SP2T-DCH (right). No single switch design meets all test needs. Tradeoffs are often required on performance, speed, and number of switching cycles.

Solid state switches, by contrast, tend to have much faster switching speeds and better repeatability over a greater number of switching cycles. These attributes are especially desirable for high-volume production test applications, as switching speed is directly related to test throughput, and the switches need to be replaced far less often under heavy use. At the same time, they come with limitations of lower power handling and lower isolation. Isolation in particular is more difficult to calibrate out of a test system and is therefore an especially critical parameter for automated testing. Switches with poor isolation can allow stray signals to flow into the measurement path and degrade the integrity of the measurement. This can impair system accuracy and lead to challenges in determining uncertainties and timing requirements.

In general, solid state switches have many advantages for high volume test applications. Below is a brief overview of how design differences between the two switch types affect key performance parameters for test setups.

Switching Speed

One of the most important differences between mechanical and solid state switch designs is in their switching speeds. When a given state is energized in a mechanical switch, a conductive reed or armature strikes an electrical contact to connect the signal from the common port to the active output. When this happens, the reed may bounce 2 or 3 times before settling, during which time the electrical contact rapidly connects and disconnects before the connection is stable. This “settling time” is considered part of the overall switching time, so while it may take 8-9 mS for the switch to change states, the settling time may add 12-15 mS to the overall switching time.

Solid state switches rely on a change in electrical field rather than moving parts and mechanical connections. There is thus no settling time, and overall switching speed is much faster – in the order of micro- and nano-seconds rather than milliseconds.

Switch Life

Because the connection in a mechanical switch relies on mechanical contact between two surfaces, in order to minimize resistance, the two surfaces need to be as flush to each other as possible. As the reed and the contact repeatedly connect and disconnect over time, the contact surfaces can change shape and wear-off oxidation can form, degrading the electrical connection and the performance of the switch.

Mini-Circuits’ mechanical switches use patented technology to guarantee switch life up to 10 million cycles and give customers outstanding longevity. The unique construction of our mechanical switch models makes it very practical to clean the switch contact assembly, enabling performance recovery and extending switch life to over 100 million cycles.

Still, solid state switches have no moving parts, and mechanical degradation of the electrical contact isn’t a problem. As a result, overall switch life is much longer than that of even the most robust mechanical switch.

Transient Voltages

Most electromechanical switches incorporate a coil to create a magnetic field. When voltage is removed from the coil, the field collapses which causes “flyback” or “kickback” of the current in the opposite direction. This can create a transient voltage which adds noise and other unwanted effects to the system and even damage other elements in the circuit. This is why mechanical switches are often outfitted with an integrated or external surge protector.

Solid state switches have no magnetic field and no kickback. Therefore, transient voltages and auxiliary surge protection are not a concern.

Isolation

Mechanical switches typically offer higher isolation than solid state switches. One of the traditional drawbacks of using solid state switches for test applications is the potential effect of stray signals on uncertainty and system accuracy. Solid state switches are typically constructed with either PIN diode switches or FET switches. PIN diode switches offer better isolation performance at high frequencies but have poorer isolation at lower frequencies (<40 MHz) due to the inherent limitations of the technology. FET switches have good isolation at low frequencies, but at higher frequencies they underperform due to the FETs’ drain-source capacitance in the off state. Today, switch designers are creating hybrid designs that optimize the desired features of both FET and PIN diode switches.

Mini-Circuits engineers have innovated solid state switch designs to dramatically improve isolation performance over wide bandwidths and circumvent some of the challenges associated with lower isolation. Mini-Circuits now offers a wide variety of cost-effective, USB-controlled solid state switches with frequencies ranging from DC to 8 GHz and isolation ranging from 50 up to 110 dB. Meanwhile these models retain the advantages of long switching life and switching speeds specified in microseconds (even nanoseconds) rather than milliseconds. Their compact, low profile size also helps reduce the overall size of the test system. Table 1 highlights the performance of a few of our solid state switch models.

Table 1. Selected examples of Mini-Circuits high-performance solid-state switches. Mini-Circuits models offer a wide range of switch configurations, control interfaces, and performance parameters.

| Model Number | U2C-1SP2T-63VH | USB-2SP2T-DCH | USB-4SP2T-63H | SPI-SP10T-63 |

| Frequency Range | 10 to 6000 MHz | DC to 8000 MHz | 10 to 6000 MHz | 1 to 6000 MHz |

| Switch Type | SPDT | Dual SPDT | Quad SPDT | SP10T |

| Isolation | 110 dB | 50 dB up to 4 GHz | 65 dB | 80 dB |

| Switching Time* | 700 ns | 14 µsec | 250 nsec | 6 µsec |

| Insertion Loss | 5.0 dB | 1.5 dB | 2.8 dB | 5.0 dB |

| Power Handling | +33 dBm | +35 dBm | + 30 dBm | +27 dBm |

*Specified without communication delays. Switching time spec represents the time that the RF signal paths are interrupted during switching.

Real World Example – Switch Matrix for Telecommunications Testing

RF and microwave switches used in real-world test applications are often configured together into a switch matrix to manage and automate signal traffic. Since all test signals pass through the switch matrix, its performance directly effects the accuracy, repeatability, and efficiency of your measurements. In building a given test setup, test engineers need to focus on getting their DUTs properly tested in the most efficient manner possible. Primary concerns are that the test solution employed delivers the correct signal at the required power level to the DUT and that the isolation between test ports maintains measurement integrity.

Determining switch matrix routing and performance for complex, application-specific test systems can become very costly and time consuming. Moreover, system requirements tend to be unique to a given application, and there’s no one-size-fits-all solution. To support customers in this task, Mini-Circuits offers a wide range of modular and fully customized integrated solutions, including high-order switch matrices for signal routing. Whether these systems incorporate mechanical or solid state switching in a given system is determined based on your specific system requirements.

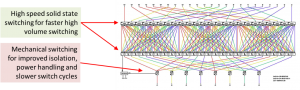

Let’s consider a real example supporting telecom test applications from 600 MHz to 6 GHz. Figure 2 highlights an 8 x 24 switch matrix subassembly. This unit was part of a larger, 24 x 48 system that included signal conditioning. In this case, the switch matrix had to provide a maximum path loss of 12 dB and provide 120 dB of isolation between test ports. The goal was to meet throughput requirements of less than 30 millisecond DUT test time.

In order to meet the design requirements, the system utilized a combination of mechanical and solid state switches. On the 8-port side we used mechanical SP4T switches (MSP4TA-18+), which provided 0.2 dB insertion loss and 90 dB isolation. The MSP4TA’s 20 millisecond switching speed meets the overall test time required at this stage of the signal routing plan.

Figure 2 illustrates the elaborate switching network beyond the SP4T switches. To accomplish this signal routing and still meet the test time requirement, we used our SPI-controlled RF SP10T solid state switches (SPI-SP10T-63). With this model’s 6 microsecond switching speed, all the solid state switching routes can be cycled in less time than the mechanical switch performs a single cycle. It also provides 80 dB isolation and +27 dBm power handling, meeting the requirements for this telecom application. The configuration in this example takes advantage of the benefits of both switching types and allows for a wide range of testing to be performed.

Figure 2. Switch matrix designs are optimized to take advantage of each switches’ unique performance parameters.

Meeting Your Requirements

As the industry works to develop a growing number and variety of wireless devices, the need for fast, efficient, and cost effective solutions for RF testing will continue to grow in kind. With this progression in mind, this article has provided a review of the features and relative advantages of the different switch types used for signal routing in RF test systems. Mini-Circuits’ solid state switches offer the advantages of fast switching and long life together with very high isolation, which is unique among switches in this class. Together with our full lineup of mechanical and solid state switches, this gives test engineers a wealth of options, whether using discrete components in their native setups, or sourcing a fully integrated solution.

Figure 3. Mini-Circuits offers a variety of methods for meeting your signal routing and conditioning needs. You can build it yourself with our components, use our online solution configurator, or work with our application specialists for a solution customized to your requirements.