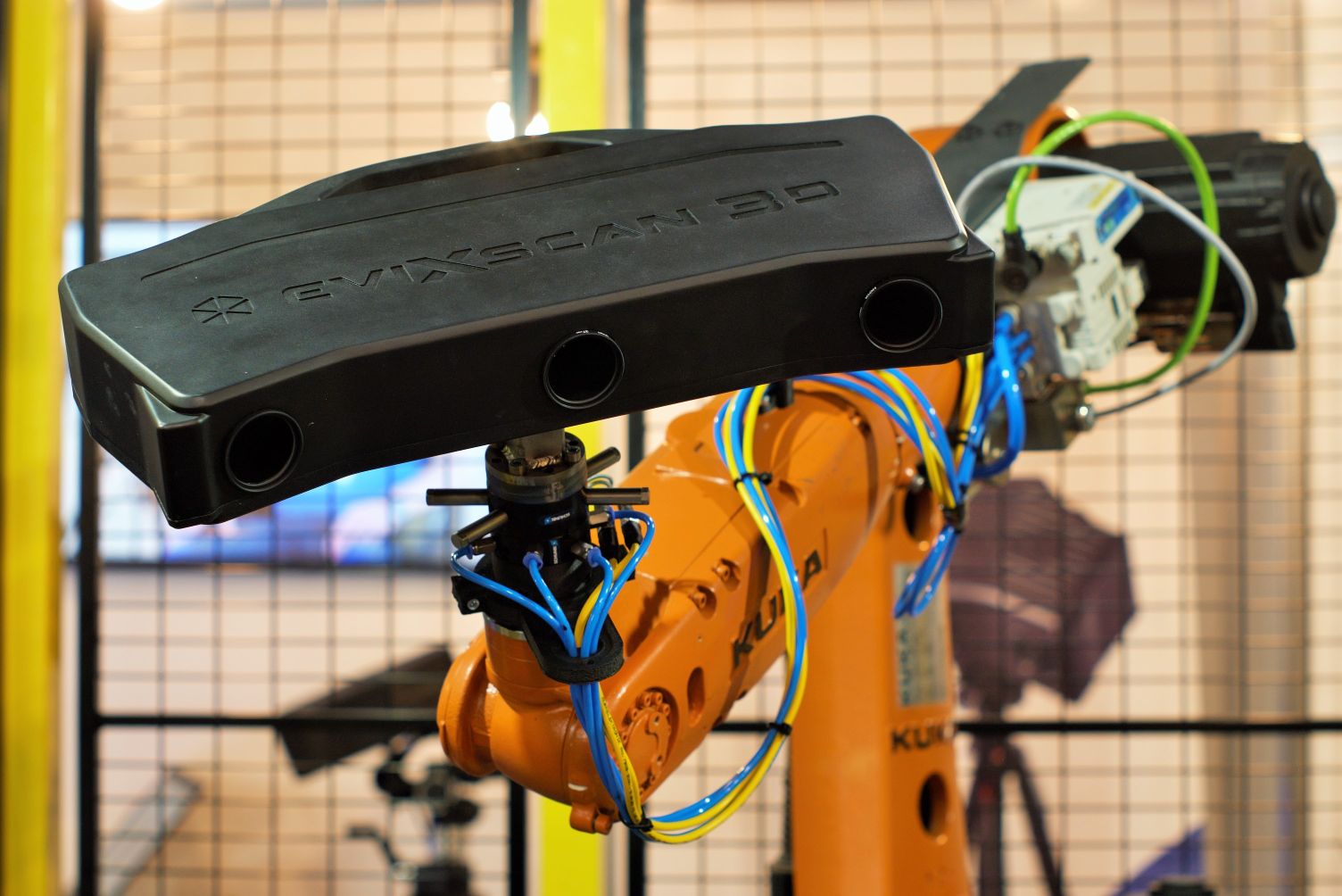

Delta Automation Sp. z o.o. and Evatronix SA are jointly developing and launching an innovative control and measurement system based on the integration of eviXscan 3D scanner with industrial robot.

“The eviXscan 3D solutions are traditionally applicable in industry for the purposes of reverse engineering, quality control and rapid prototyping,” says Adam Morawiec, Vice-President for Development of Evatronix SA. “The collaboration with Delta Automation opens completely new areas of application for our scanners. It’s a giant step towards Industry 4.0.”

The integration of industrial robot with eviXscan 3D scanner enables contactless correction of the robot’s path by reading the processed object’s position, as well as performing the measurements for detection of presence of the components applied by the industrial robot. The control and measurement system developed by Evatronix and Delta Automation is applicable in determining the quality and accuracy of engineering processes, among other things, it enables the contactless quality control of a manufactured element. Another functionality of the integration of eviXscan 3D scanner with the robot is the automated, accurate scanning of objects for the purposes of rapid prototyping.

“We decided to collaborate with Evatronix SA to develop the control and measurement technology,” says Adrian Stodolny, the President of the Management Board of Delta Automation Sp. z o.o. “The solution we have developed is applicable in many areas of industry, for instance, in the automotive industry where the highest accuracy of the engineering processes is required.”