Leading semiconductor test equipment supplier Advantest Corporation (TSE: 6857) has extended the performance of its V93000 single scalable platform with the FVI16 floating power VI source for testing power and analog ICs used in automotive, industrial and consumer mobile-charging applications such as the growing e-mobility and rapid charger market. By supplying 250 watts of high-pulse power and up to 40 watts of DC power, the new source helps to provide sufficient power testing latest generation devices while conducting stable and repeatable measurements.

“Our enhanced power resource gives the V93000 platform the industry’s best VI signal performance and expands its coverage into new markets, making it the broadest test solution available,” said Hans-Juergen Wagner, senior vice president, SoC Business Group at Advantest. “With the FVI16, this versatile test platform is equipped for testing semiconductors for a wider range of power-management devices, from airbags and ABS (anti-lock braking system) controllers to USB-C chargers and cordless power tools.”

The system’s digital feedback loop design provides the best source, measurement accuracy and analog/power performance on the market, compared to competitors’ systems that operate with a traditional analog feedback. Digital feedback technology offers several unique features including spike-free “smart connections” with constant Kelvin monitoring for reliable and highly precise measurements. User-controllable slew rate and bandwidth settings allow fast settling times adapted to the respective load conditions.

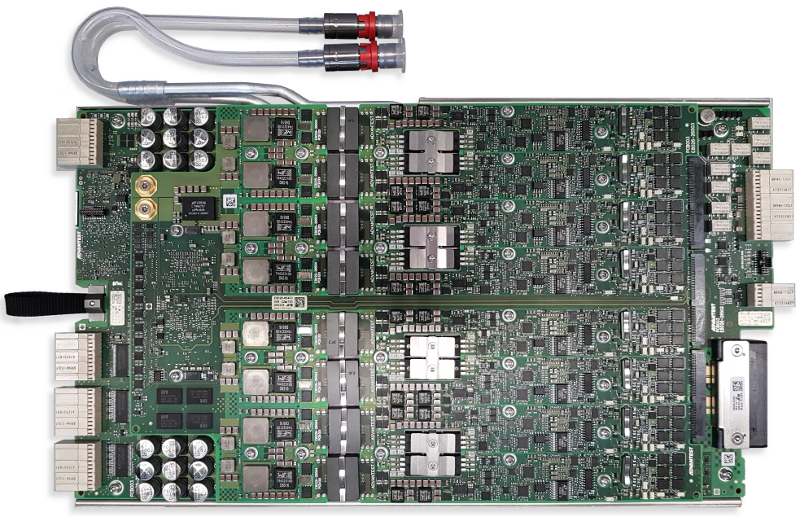

The FVI16 unit features the industry’s highest instrument-channel density, enabling small system configurations that fit into Advantest’s A-Class test head and therefore lowers cost of test. Sixteen channels with four-quadrant operation allow for source ganging of up to 155 amps per card on high-current tests. For high-voltage testing, source stacking of up to +180 volts per card within a floating range of + 200 volts can be achieved.

The FVI16’s patented integrated fast current clamp protects the loadboard hardware, probe card pins and DUT sockets in case a damaged device creates a short circuit.

Customers can use the new FVI16 to extend the capabilities of their existing V93000 Smart Scale systems to the higher voltages, increased channel count and power demands for high-site-count IC testing while maintaining a low cost of test.

Already in use at several customer sites, the FVI16 floating power VI source has generated multiple orders from leading automotive customers in Europe and Japan. Advantest is offering flexible licensing arrangements that allow customers to select the best fit for their specific needs.