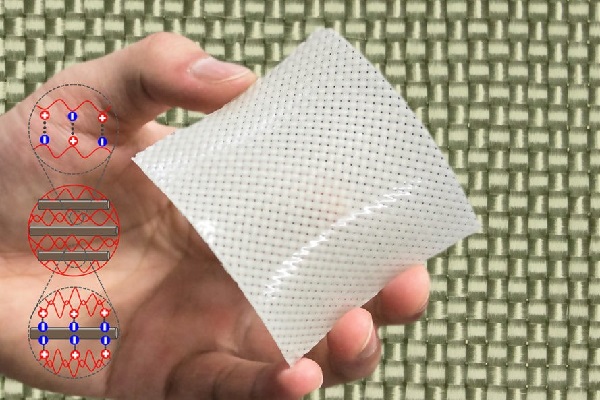

Researchers at Hokkaido University in Japan have created a flexible, eco-friendly material that’s five-times stronger than carbon steel. The “fiber-reinforced soft composite” made by combining polyampholyte hydrogels with woven glass fiber fabric creates a bendable material that’s extremely durable. The material’s uses are manifold, but perhaps most exciting is for bearing the load of artificial ligaments and tendons.

Hydrogels have been used for a variety of applications in the past, from wound dressings to soft robots, but up until recently the hydrophilic polymer chains have been too soft for much else due to the fact that they’re largely made up of water. But when woven together with glass fiber fabric, they create a material that’s not only stronger than steel, but according to researcher Dr. Jian Ping Gong, also environmentally friendly.

“The fiber-reinforced hydrogels, with a 40 percent water level, are environmentally friendly,” says Dr. Jianinnovation. “The material has multiple potential applications because of its reliability, durability and flexibility. For example, in addition to fashion and manufacturing uses, it could be used as artificial ligaments and tendons, which are subject to strong load-bearing tensions.”

While the material is made largely from water and glass, it gains its strength from the dynamic ionic bonds between the fiber and hydrogels. The team found that a combination of polyampholyte gels, a type of hydrogel they developed earlier, and glass fiber fabric with a single fiber measuring around 10μm in diameter produced a strong, tensile material.

Testing revealed that the material is 25-times tougher than glass fabric, 100-times stronger than hydrogels alone, and five-times stronger than carbon steel.