Smart LED lighting systems in various fields – from home to commercial to public applications – are taking off at great speed. The U.S. market researcher IHS projects over 160 Million smart lighting systems to be sold in commercial applications this year, with a CAGR of over 40 percent through 2018. This is due to their inherent advantages, such as low power consumption, dimmability and choice of color, flexibility in size and easiness of combining to form LED strips. These capabilities are key for creating attractive lighting solutions according to the customers’ architectural guidelines and preferences. One frequent problem that industrial lighting designers have when they are developing smart LED solutions is not having the necessary power supply expertise, which was not a key competency before LED lighting took off.

Another difficulty for inexperienced LED lighting designers arises when systems have to be designed for various wattage levels. The complaint heard most often is that it takes lighting product designers too long to respond to different wattage specifications because each single solution tends to be customized. This implies devising different semiconductor controller circuits, along with different magnetic components. The result is that LED solutions for industrial and commercial lighting systems tend to be expensive.

The commonly used driver solution in LED lighting products is based on switched mode power supply (SMPS) technology. Although well proven and reliable, SMPS-based drivers do not offer the advantages of LED lighting engines with newer Direct AC Drive (DACD) technology.

The Flicker Problem

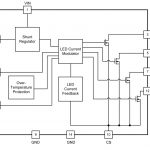

- Figure 1. Simplified Block Diagram of the LF77944 LED Driver.

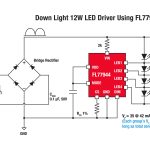

- Figure 2. 12-W LED Downlight Application with FL77944.

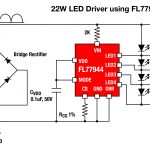

- Figure 3. 22W LED Driver Circuit with LF77944.

The DACD advantages, such as lower cost, smaller form factor, much higher performance and a longer system lifetime are compelling. Yet DACD has been slow to take off, particularly in the commercial and industrial market segments. A key reason is the issue of flicker. Flicker occurs when the AC line to supply the LED system goes through the zero crossing points of its sinusoidal trajectory at twice the powerline frequency of 100/120 Hz. This means the supply voltage momentarily drops to zero and the LEDs switch off, which sometimes causes the effect of a perceptible flicker.

Flicker is not always an issue, but it can be problematic for offices, schools, stores and other brightly lit commercial and industrial spaces, as well as for live video recordings and smartphones.

Flicker Specs and Solutions

The basic solution to the often disturbing flicker effect is to keep LEDs excited during the AC line voltage drops. This seems like an easy enough remedy. But the practical solutions can be problematic. Thus, up to now, DACD suppliers have used traditional approaches of energy storage to keep the LEDs excited. While this basically solves the flicker effect, it also causes distortion to the input line current waveform. This impacts the power factor (PF) and total harmonic distortion (THD) performance of those LED lighting systems.

This is a particular problem in those industrial and commercial lighting products that have to meet the accepted guidelines for PF and THD performance. Typical specifications require a PF of 0.9 or greater. THD typically needs to be less than 20 percent. There are currently no standards governing flicker. Most manufacturers and customers accept the US ENERGY STAR recommended spec for calculating the flicker index. It suggests a figure of 0.15 or lower to be optimal since values below 0.15 are considered imperceptible. As a consequence, lighting manufacturers typically aim to achieve or improve on this limit.

Direct AC Driver for Superior Performance

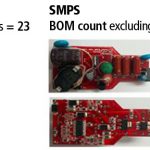

- Figure 4. LED Board based on the LF77944.

- Figure 5. Minimum component count (excluding LEDs) 23 vs 62…one board vs two and the SMPS’ second board is two-sided board

All these problems are now being addressed, as Fairchild, a leading global supplier of high-performance semiconductor solutions, recently introduced its new FL77944 LED Direct AC Drive family of solid-state LED lighting solutions. The FL77944 and the IP provided by Fairchild enable a tunable flicker index below 0.10 while maintaining PF > 0.9 and THD < 20%. LED lighting manufacturers can use these integrated driver circuits to easily scale power conditions. This will enable them to create smart and scalable LED systems that are smaller, have higher performance and reliability, offer size advantages and a lower component count as well as longer lifetimes compared to the traditional SMPS approach.

The FL77944 is a cost-effective integrated circuit with everything manufacturers need for smart LED lighting products so they can accelerate time-to-market and focus on differentiating features, rather than spending precious time cobbling together disparate components.

The new Fairchild FL77944 DACD solution offers:

- Comprehensive dimming capabilities. It enables all the dimming capabilities required for smart lighting products, including phase-cut dimming as well as analog and PWM dimming, which is key for wirelessly connected lighting.

- Scaling for higher power applications. The Fairchild FL77944 can scale upwards to suit higher power applications well above 120W. This is simply done by wiring products in parallel. It also reduces the number of different ICs that lighting manufacturers need to keep in inventory.

- Elimination of electrolytic capacitors. System designs with the FL77944 can eliminate the electrolytic caps, transformers and inductance coils. This reduces both the bill-of-materials (BOM) costs and the overall complexity compared to designs using SMPS.

- Reduced board space. Locating the controller IC on the same PCBs as the LEDs, aided by the absence of electrolytic caps, transformers and inductance coils enables more compact lighting designs.

- Tunable Flicker reduction. With the addition of external energy storage capacitors, the flicker index can be tuned to application acceptable levels while meeting PF > 0.9 and THD < 20%.

- Improved reliability and lifetime. LED products based on the FL77944 should be more reliable and last significantly longer than SMPS-based products as there are fewer points of failure. Eliminating electrolytic capacitors removes the most common source of failures in SMPS-based products.

To sum up the FL77944 value proposition: It is the simplest, most cost effective lighting solution currently on the market. It provides best-in-class light quality that meets high PF and low THD requirements, along with various dimming principles. It is suited for indoor and outdoor applications, including down light, tube light, high bay, flood light and street light systems.

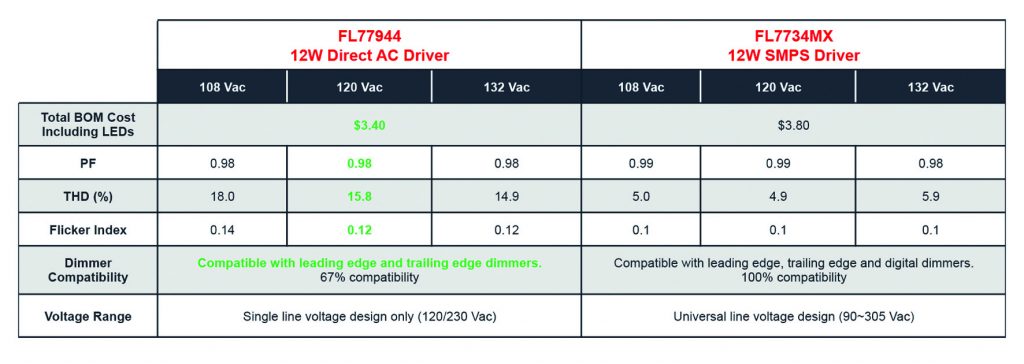

Table. Comparison between 12W DACD LED driver and SMPS solution

Evaluation Board Now Available

At the recent PCIM Europe trade fair (10 – 12 May 2016 in Nuremberg, Germany) Fairchild also demonstrated the FEBFL77944 evaluation board for systems designers. Visit Fairchild’s LED Direct AC Drive blog, lighting solutions guide and Direct AC Drive website for detailed product information, datasheets and evaluation boards.