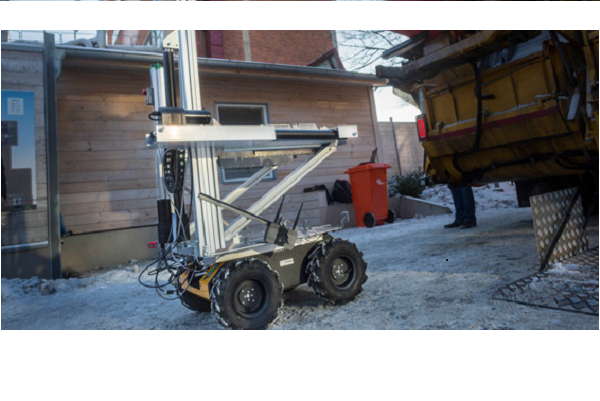

Students from three universities have collaborated with the Volvo Group and the waste recycling company, Renova. The result is a robot that automatically collects and empties refuse bins. A drone on the roof of the refuse truck scans the area and helps the robot to find the bins.

When it is time to begin waste collection, the driver of the refuse truck presses a button. This starts the robot, and the drone simultaneously lifts from the roof of the truck. Flying through alleyways, the drone quickly finds the location of the refuse bins and communicates their positions to the robot. This is followed by automatic waste collection and emptying by the robot. In the cab, the driver is able to monitor the exact location of the robot and the emptying process.

The ROAR project, Robot-based Autonomous Refuse handling, is a collaboration between the Volvo Group, Chalmers University of Technology, Mälardalen University, Penn State University in the United States, and Renova. The objective of ROAR is to demonstrate how smart machines will soon be able to communicate with each other to facilitate everyday life in a large number of areas.

“We predict a future with more automation,” says Per-Lage Götvall, project manager for robot development in the Volvo Group. “This project is intended to stimulate our imagination, to test new concepts that may shape transport solutions of the future.”

In technical terms, a prerequisite for the robot’s work is that it already knows the neighborhood in the form of a map of both the maneuverable area and likely bin locations. The robot then uses a number of different sensors to keep itself positioned within this map, enabling it to automatically perform its tasks. The sensors include GPS, LiDAR (a system similar to radar but using infrared light instead of radio waves), cameras, and IMU data, which uses accelerometers and gyroscope for navigation as well as odometry, where motion sensors measure the position changes over time.

“For us at the Volvo Group, the safety aspect forms the basis of everything we do,” says Per-Lage Götvall. “Accordingly, many of the robot’s sensors are also used to ensure safety”.

One example is an emergency button, which immediately stops the robot if, for example, a child or a dog runs out in front of it. Another example is a camera on the truck that detects if someone comes too close while the bins are being emptied. If this occurs, the process automatically stops.

The students who worked on the project are all from universities that are included in the Volvo Group’s Academic Partner Program, a network of 12 universities with long-term research and recruitment collaboration with the Volvo Group.

It took students and researchers from the three participating universities only four months to design and build the prototype robot that automatically collects and empties the refuse bins. Mälardalen University was responsible for designing the robot itself and Chalmers University of Technology developed the task-management system for the robot and the drone. Penn State University developed the graphics that enable the driver in the cab to have an overview of all the systems, or to even control the robot’s motion directly.

Picture: www.volvogroup.com