Materials science and mathematics combine to enable the printing of shapeshifting architectures that mimic the natural movements of plants

A team of scientists at the Wyss Institute for Biologically Inspired Engineering at Harvard University and the Harvard John A. Paulson School of Engineering and Applied Sciences has evolved their microscale 3D printing technology to the fourth dimension, time. Inspired by natural structures like plants, which respond and change their form over time according to environmental stimuli, the team has unveiled 4D-printed hydrogel composite structures that change shape upon immersion in water.

“This work represents an elegant advance in programmable materials assembly, made possible by a multidisciplinary approach,” said Jennifer Lewis, Sc.D., senior author on the new study. “We have now gone beyond integrating form and function to create transformable architectures.”

Lewis is a Core Faculty member at the Wyss Institute for Biologically Inspired Engineering at Harvard University and the Hansjörg Wyss Professor of Biologically Inspired Engineering at the Harvard John A. Paulson School of Engineering and Applied Science (SEAS). L. Mahadevan, Ph.D., a Wyss Core Faculty member as well as the Lola England de Valpine Professor of Applied Mathematics, Professor of Organismic and Evolutionary Biology, and Professor of Physics at Harvard University and Harvard SEAS, is a co-author on the study. Their team also includes co-author, Ralph Nuzzo, Ph.D., the G.L. Clark Professor of Chemistry at the University of Illinois at Urbana-Champaign.

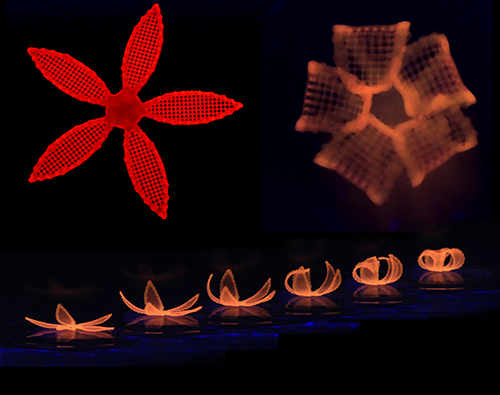

In nature, flowers and plants have tissue compositions and microstructures that result in dynamic morphologies that change according to their environments. Mimicking the variety of shape changes undergone by plant organs such as tendrils, leaves, and flowers in response to environmental stimuli like humidity and/or temperature, the 4D-printed hydrogel composites developed by Lewis and her team are programmed to contain precise, localized swelling behaviors. Importantly, the hydrogel composites contain cellulose fibrils that are derived from wood and are similar to the microstructures that enable shape changes in plants.

Reported on January 25 in a new study in Nature Materials, the 4D printing advance combined materials science and mathematics through the involvement of the study’s co-lead authors A. Sydney Gladman, who is a graduate research assistant advised by Lewis and specializing in the printing of polymers and composites at the Wyss Institute and SEAS, and Elisabetta Matsumoto, Ph.D., who is a postdoctoral fellow at the Wyss and SEAS advised by Mahadevan and specializing in condensed matter and material physics.

By aligning cellulose fibrils during printing, the hydrogel composite ink is encoded with anisotropic swelling and stiffness, which can be patterned to produce intricate shape changes. The anisotropic nature of the cellulose fibrils gives rise to varied directional properties that can be predicted and controlled. This is the reason that wood can be split easier along the grain rather than across it. Likewise, when immersed in water, the hydrogel-cellulose fibril ink undergoes differential swelling behavior along and orthogonal to the printing path. Combined with a proprietary mathematical model developed by the team that predicts how a 4D object must be printed to achieve prescribed transformable shapes, the new method opens up many new and exciting potential applications for 4D printing technology including smart textiles, soft electronics, biomedical devices, and tissue engineering.

“Using one composite ink printed in a single step, we can achieve shape-changing hydrogel geometries containing more complexity than any other technique, and we can do so simply by modifying the print path,” said Gladman. “What’s more, we can interchange different materials to tune for properties such as conductivity or biocompatibility.”

The composite ink that the team uses flows like liquid through the printhead, yet rapidly solidifies once printed. A variety of hydrogel materials can be used interchangeably resulting in different stimuli-responsive behaviors, while the cellulose fibrils can be replaced with other anisotropic fillers of choice, including conductive fillers.

“Our mathematical model prescribes the printing pathways required to achieve the desired shape-transforming response,” said Matsumoto. “We can control the curvature both discretely and continuously using our entirely tunable and programmable method.”

Specifically, the mathematical modeling solves the “inverse problem”, which is the challenge of being able to predict what the printing toolpath must be in order to encode swelling behaviors toward achieving a specific desired target shape.

“It is wonderful to be able to design and realize, in an engineered structure, some of nature’s solutions,” said Mahadevan, who has studied phenomena such as how botanical tendrils coil, how flowers bloom, and how pine cones open and close. “By solving the inverse problem, we are now able to reverse-engineer the problem and determine how to vary local inhomogeneity, i.e. the spacing between the printed ink filaments, and the anisotropy, i.e. the direction of these filaments, to control the spatiotemporal response of these shapeshifting sheets.”

“What’s remarkable about this 4D printing advance made by Jennifer and her team is that it enables the design of almost any arbitrary, transformable shape from a wide range of available materials with different properties and potential applications, truly establishing a new platform for printing self-assembling, dynamic microscale structures that could be applied to a broad range of industrial and medical applications,” said Wyss Institute Founding Director Donald Ingber, M.D., Ph.D., who is also the Judah Folkman Professor of Vascular Biology at Harvard Medical School and the Vascular Biology Program at Boston Children’s Hospital and Professor of Bioengineering at Harvard SEAS.

This work was supported by funding from the Army Research Office (ARO) and the National Science Foundation’s Materials Research Science and Engineering Center (MRSEC).

FEATURED: This series of images shows the transformation of a 4D-printed hydrogel composite structure after its submersion in water. Credit: Wyss Institute at Harvard University

The round was led by the fund of Dan Caine, Chairman of the Joint Chiefs…

Company raises $5.75M to lead the shift toward AI Engine Optimization Brandlight, the first-of-its-kind AI…

Infineon further strengthens its number one position in automotive microcontrollers and boosts systems capabilities for…

Rohde & Schwarz has achieved a significant milestone, receiving approval of detection capability from the…

April 8, 2025 - Avnet ASIC, a leading provider of ASIC and SoC full turnkey…

Acquisition expands Siemens’ offering in PCB design for the SMB market and enables greater process…