With the roll-to-roll overmoulding manufacturing process developed by VTT Technical Research Centre of Finland, components can be easily overmoulded into durable electronics products such as wearable sports solutions, toys and, for instance, household appliances equipped with an overmoulded solar cell.

The jointly funded project coordinated by VTT has once more achieved significant results promoting the birth of printable, flexible and functional electronics, services and commercial business in Finland. In line with its name, the Printed Into Products 2 project fosters the growth of the industrial manufacturing of printed intelligence by different companies.

“VTT’s roll-to-roll overmoulding manufacturing process combined the printing, component assembly and overmoulding of components. The results we achieved show that it is easy to overmould components assembled onto a flexible film into durable products,” states Project Manager Tapio Ritvonen from VTT.

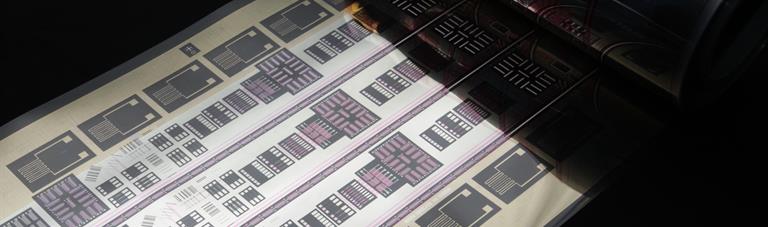

In practice, this means that conductors, circuit boards and sensors, for instance, are printed onto a film, with the resulting electronic components then assembled by an assembly machine. Finally, the structure is overmoulded with plastic.

Oulu University of Applied Sciences carried out extensive series of tests on the products manufactured using this process, investigating the durability of the structures by means of salt spraying and various mechanical tests, for example.

A printable and modelled transistor was also developed with the roll-to-roll printing process during the project. Precision printing was tested at the same time, and was found to be the most precise in the world by achieving a 2-micrometre line width with equalline gap. During the project, the University of Oulu developed a measurement method for the quality assurance of industrial production, based on synchronised thermography, where a thermal camera locates any defects in a printed, conductive structure.

Satisfied companies

One of the corporate partners involved in the project, the measurement equipment supplier Focalspec, found that its front row seat in the development and testing of cutting-edge technologies brought it concrete product development benefits. “The optical scanner solution developed during the project can measure 3D contours of a surface and determine, for example, the layer thickness of a printed pattern with sub-micrometre precision,” says Karri Niemelä, Vice President, Research and Development.

“For us, the joint project offered a smooth entry into the TEKES project,” says Hannu Valkonen, CEO of Ultracom, the developer of the accurate and lightweight Novus dog tracker.

Clothing+, in turn, focused on the data transfer properties of printed conductors in wearable products. “Our development work continues, and we intend to utilise the research results obtained now in future customer projects to a larger extent,” said Project Manager Anni Varis.

Flexbright, a manufacturer of flexible LED light foils, was another project partner. The technology it uses was developed in cooperation with PrintoCent and VTT’s Oulu unit. “Our involvement has reinforced our own product development, and the groundwork done by the research institutes strongly supports the production prospects of the companies,” states CEO Pekka Makkonen. During the project, Flexbright also developed a functional demonstration combining intelligence and wireless control with light foils for prospective Internet of Things applications.

Printed intelligence revolutionises production processes

Printed intelligence is currently considered to be one of the possible game changers for industrial production in Finland. “Finland is one of the only places in the world where the industrial production of ideas related to printed intelligence can be tested in practice. We are genuine pioneers in this field, and it is possible that technological innovations such as printed intelligence will turn the tide and restart the growth of industrial production in Finland in the near future. When combined with hybrid integration, printed intelligence will revolutionise the manufacturing process of certain components and products, and it is very cost-effective and fast compared with traditional production methods,” says Ilkka Kaisto, Director of PrintoCent.

Even today, electronics can be produced cost-effectively through printing. Printed intelligence can be utilised in the industrial mass production of diagnostic tools for the medical industry, such as rapid diagnostic tests, LED lights and batteries, for example.