The extreme operating conditions of the space environment combined with lack of access for repairs and zero tolerance for failure necessitate intensive qualification of electronic parts used in space missions. Mini-Circuits has a successful track record of supplying components for space applications, and our experience in this area has led to robust testing and qualification processes for the parts we supply for these systems.

Qualification requirements for space applications vary by program, materials and component type. Mini-Circuits offers a variety of components available for hi-rel screening including amplifiers, mixers, filters, limiters, attenuators, and more. Mini-Circuits’ LTCC filters feature rugged ceramic construction, wide operating temperature range (-55 to +100˚C), and high power handling in a tiny device size, making them excellent candidates for hi-rel applications. This article will describe the qualification process for a surface-mount LTCC low pass filter supplied for use in a particular spaceborne system. This is a case study intended to highlight Mini-Circuits’ advanced capabilities in meeting qualification requirements to ensure high reliability for space missions, but is by no means an exhaustive representation of our qualification processes.

Screening Requirements

The LTCC filter screened for in this case is a modification of standard model LFCN-8400+ satisfying a series of special screening requirements defined by a specific space flight program. The special model satisfies a material restriction that the unit terminations be constructed with tin-lead finish with a maximum tin content of 97%. This is a standard requirement to prevent tin whisker growth. The special part also satisfies a date code restriction that shipped parts may be from a maximum of two lot date codes. If parts are shipped from two lots, one lot must be from new production and both lots must have passed screening independently.

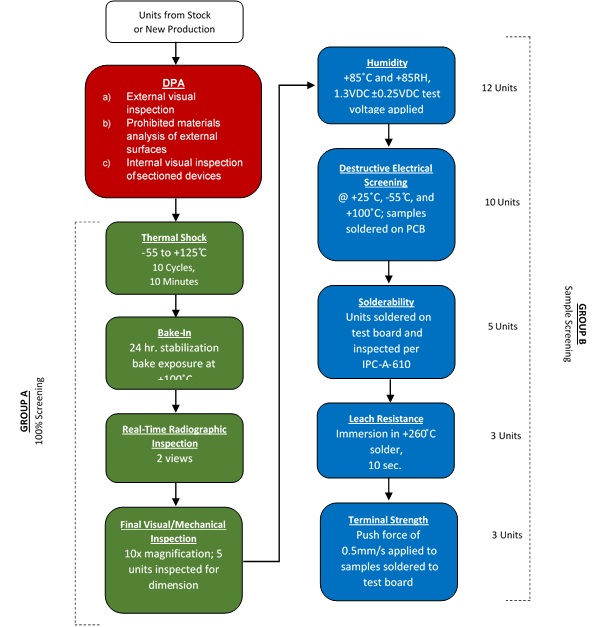

Destructive Physical Analysis (DPA) is required on sample units from lots used for production to verify construction and termination composition. Units must also undergo a rigorous program of reliability testing including real time radiographic inspection in three views. The full qualification process performed to meet the program requirements is summarized below.

Qualification Process

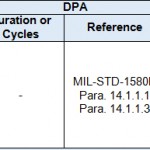

1. Destructive Physical Analysis (DPA)

2. Reliability TestingPrior to starting reliability testing, DPA is performed on 3 randomly selected sample units to verify the construction and termination composition on the lot to be used for production. MIL-STD-1580B is used to establish a general process for performing DPA on the units under test, but because pass/fail criteria for LTCC unites are not defined by the standard, it is used as a guideline, and the units under test are compared to determine if there are any apparent anomalies. The DPA pass/fail criteria are summarized in Table 1.

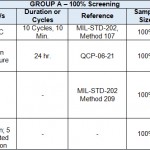

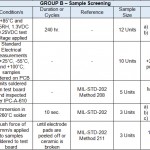

Following DPA, reliability testing consists of testing at 100% (Group A) and small sample testing (Group B) for a number of parameters summarized in Table 1.

Table 1: Screening process summary

Figure 2: Qualification flow for LTCC low pass filter for a specific space flight program.

Conclusion

The qualification process presented here satisfies requirements for an LTCC low pass filter to be used in a particular space application. Mini-Circuits’ line of LTCC filters includes over 195 high-pass, low-pass and band-pass models available for hi-rel screening in addition to a wide selection of hi-rel mixers, amplifiers, attenuators, limiters, and other components suitable for space applications. Requirements vary widely depending on many factors including the component type, materials, and other details specific to the flight program. Mini-Circuits has successfully screened hi-rel components for a range of space requirements, and this experience has enabled us to develop well-established qualification processes for these demanding applications. For more information about qualifying parts for space applications, please contact our applications team at apps@minicircuits.com to discuss how we can support your specific requirements.Conclusion