The Vicor approach

- Offers great design flexibility • Enables the designer to optimise system performance through the selection of the right components • Streamlines the development process when supported by design automation software

The architectural problems of power conversion

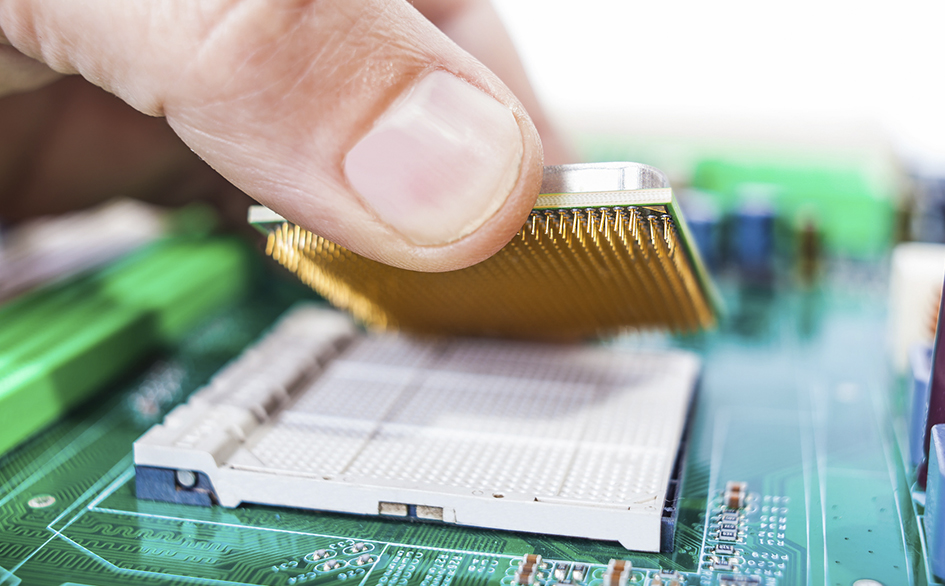

With each new generation of processor, memory technology and ASIC, system designers face the challenge of handling lower voltages, higher currents, higher speeds andmore on-board voltages. At the same time, they have to: • Provide ever-faster transient responses • Achieve higher power-system efficiency • Use less board space

Vicor’s product range supports a component-based design technique for the development of such high-performance power supplies, allowing the designer to optimise them for each specific end product. The Vicor range of power components (normally housed in small, low-profile packages similar to electronic components) addresses the entire power chain from the mains source to the point-of-load (PoL). Vicor front-end modules, intermediate-stage converters and PoL DC-DC converters may be successfully used in applications with loads ranging between 25W at the low end and 1kW at the high end. A complete source-to-PoL power chain can be quickly developed from the Vicor range of power components. System designers benefit particularly from the Vicor component approach to their power-supply design when their requirement is for one or more of the following

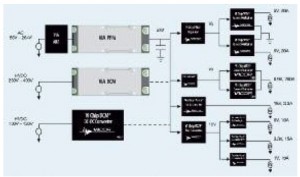

Fig. 1: a complete source-to-PoL power chain can be quickly developed from the Vicor range

of power ‘components’

Small size – Vicor uses resonant power-conversion topologies which draw on advanced high-frequency switching techniques to realise components with a remarkably small footprint and low profile.

High efficiency – achieving almost lossless switching, Vicor components generate very little waste heat. This often enables system designers to dispense with the bulky heat sinks and unreliable fans required in conventional power supplies

Fast design – because Vicor’s components are designed to work together, the designer can move quickly from component selection to prototype development and testing. Interoperability between one Vicor component and another is handled automatically by Vicor’s design software.

Design flexibility – the building block approach enables the designer to quickly substitute one Vicor power supply component for another should a load, voltage or other system parameter change.

Users gain the full benefit of the Vicor component methodology when integrating Vicor components all the way from the source to the PoL. This is for two reasons: • The Vicor PowerBench™ suite provides design tools and references allowing engineers to select, configure and implement Vicor components quickly and easily. Vicor’s algorithms underpinning the entire suite ensure that product combinations selected in PowerBench will work well, and predictably. • High-voltage power distribution is supported natively by the Vicor product portfolio. Power system architects understand the advantages of distributing power at the highest possible voltage: this reduces transmission losses, enables the use of thinner power cables, and provides for higher conversion efficiencies. Vicor power components readily step down directly from 24V, 36V or 48V to PoL voltages. Designers can replace the conventional 12V power bus with a 24V or 48V solution and benefit from a reduced component count and improved system performance. System designers evaluating Vicor components for the first time may draw on the expert technical support available from Future Power Solutions in every region of Europe. They may also find detailed information about Vicor components, the PowerBench tool suite and high-voltage power distribution at the Vicor web site – vicorpower.com

End product types that could benefit from the use of Vicor power components

LED information display panels

- Surface-mount LEDs on large boards • Power modules are typically on the back side • Heat from the power supply can change the LEDs’ output • Power to the board is either 48VIN or 24VIN • Nominal 48VIN withstands 60V maximum • Isolation is provided upstream • Output voltages to LED drivers are 3.3V, 5V and 12V • Supports loads of hundreds of Watts • Trend for migration to full-colour displays P13xxx Cool-Power ZVS Buck Regulators • Best-in-class density and efficiency • 12V, 24V and 48V nominal buck regulators • LGA package

Test equipment and instrumentation

Today’s AC-DC power systems need to be small, reliable, easy to use, and cost-competitive while achieving the latest requirements for efficiency, power factor, and conducted and radiated emissions. Vicor has solved these difficult challenges by combining advanced power-conversion engines. Because Vicor systems offer higher efficiency, they can operate with a smaller heat sink and no fan, enabling systems with higher output power in 19” rack-mount systems.

PFM™ Isolated AC-DC Converters with PFC

- Small size, low profile • Thermally efficient design often eliminates the need for a fan • Integrated filtering, transient protection and inrush current protection • Efficiency up to 92%

Broadcast equipment

The use of Vicor power components supports trends including: • Migration from 12V and 24V input bus voltages towards higher voltages such as 48V. • Higher efficiency, not only in high-power systems and batterypowered systems, but also in lowpower and Sleep mode operation.

BCM® Low Voltage Bus Converter Modules

• Non-regulated, isolated bus-converter module • 48V input, 3V to 48V output • Supports loads up to 1,950W • Up to 97.9% efficiency

Electric and hybrid electric vehicles

A wide range of power loads must be supplied, from the main traction system through to low-voltage peripherals such as navigation systems and dashboard information displays. Vicor components enable the designer to support a wide

DCM™ DC-DC Converter Modules

- Regulated, isolated DC-DC conversion • Up to 94% efficiency • Up to 1,200W/in3 • Supports input voltages ranging between 160V and 420V