Now tiny chip-scale devices can replace bulky brick power supplies without sacrificing power-handling capability

The designers of a wide range of military equipment face a common challenge when specifying the power supply: how to reduce the size, weight and power losses while maintaining the required inputs and outputs.

Whether carried by soldiers on the battlefield, mounted in a jet fighter, attack helicopter or missile, or squeezed inside a submarine, much military electronic equipment must be as small and light as possible in order to maximise operational effectiveness. In a power supply, this calls for high efficiency, since any reduction in power losses also cuts the amount of waste heat it generates. With less heat to dissipate, the power supply can be accommodated in a smaller case, with a smaller heat sink and less free space reserved for cooling airflows.

For more than three decades, Vicor has been providing military commercial off-the-shelf (MIL-COTS) power supplies that meet this need for extreme size, weight and power characteristics. Still today, brick power supplies such as the VIPAC family of power systems boast good power density, while satisfying military requirements for transient voltage protection, shock and vibration capability and EMI

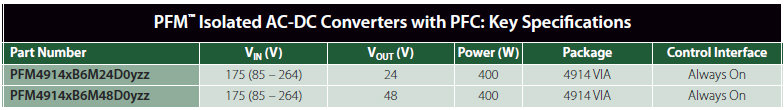

The VIA PFM™ isolated AC-DC converter with

power factor correction. The 4914 VIA package

measures 125mm x 36mm x 9.4mm

compliance.

These and other Vicor products provide for the 270V DC and 28V DC power rails commonly implemented in military power supplies. Increasingly, however, military equipment designers are looking to 48V DC as a standard power bus which can offer a wider range of commercially attractive power components.

Chip-scale power supplies save space and weight

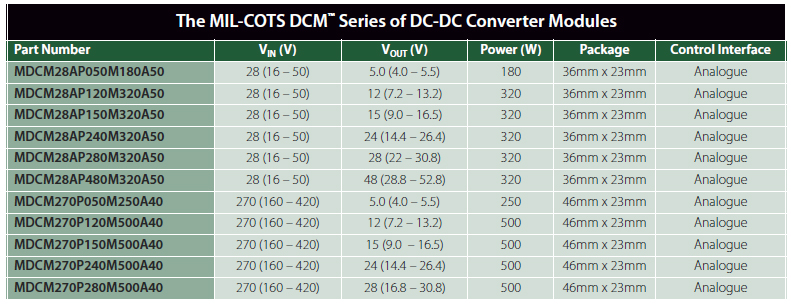

Recent innovations, however, have created new opportunities for system designers to make even more radical savings in size, weight and power. First, Vicor developed the MIL-COTS DCM™, a series of isolated, regulated DC-DC converter modules. The DCM series is housed in Vicor’s ChiP technology, an enclosed, low-profile rectangular package with a similar footprint and profile to a semiconductor’s. Benefiting from low thermal impedance on both top and bottom faces, the DCM modules achieve remarkably high power density, offer efficiency of up to 93%, and support an operating temperature range of -55°C to 125°C.

New, smaller VIA package

Newly introduced in 2015, the supremely thermally efficient VIA package takes the power supply’s density to an even higher level. The VIA package houses the DCM module (or an AC-DC module), while integrating additional functions: filtering and transient voltage suppression. Providing a thermal interface at top, bottom or sides, the tiny VIA DCM packages give system designers unprecedented mechanical design flexibility while supporting higher power outputs in a smaller system footprint, since they eliminate the external filters and transient suppression devices required when using

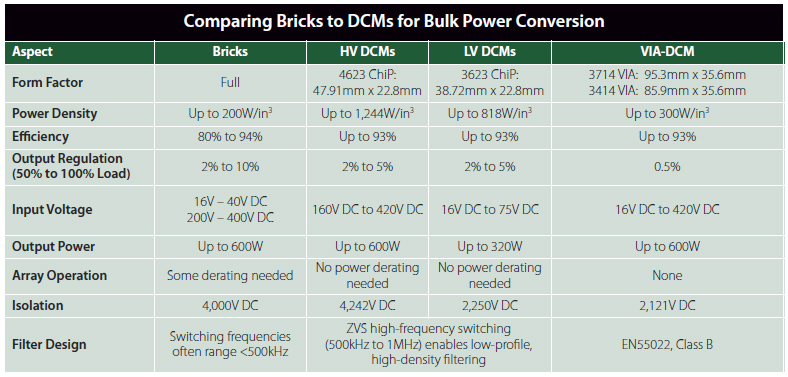

Unprecedented power density From traditional bricks