Introduction

As a standard for serial communication to peripheral devices, USB is ubiquitous today. However, industrial devices still rely in many cases on the older standard of RS-232 for debug or master-slave connections. In order to add robustness through differential communication, RS-422 or RS-485 are also widely used, and RS-485 remains the physical layer standard used by various wired multi-node industrial network or Fieldbus protocols. As a result, there can be a mismatch between the available interfaces on tools used for debugging or monitoring, such as laptop computers that only have USB for serial communications, and industrial equipment, which may only expose RS-232, RS-422 or RS-485 interfaces.

In addition to the hardware interfaces required for any USB to UART translation, galvanic isolation is a functional and potentially safety requirement for any interface circuit between test or monitoring equipment, and industrial equipment that is potentially in active use, in an electrically harsh environment. Combinations of interface, iCoupler and isoPower isolation technology from Analog Devices, integrated together in a variety of ICs, allow easy solutions for bridging the gap between USB and traditional industrial interfaces.

Why use galvanic isolation?

When interfacing with industrial equipment, it is of paramount importance to avoid interfering with the operation of those systems. Galvanic isolation prevents any flow of current while allowing data transfer, protecting both the unit under test and the debug unit. When connecting debug consoles (for example, laptop computers), several hazards are apparent, as shown in Figure 1.

– If the debug equipment is grounded, differences in ground potentials can result in loop currents

– If the debug equipment is not grounded, static can discharge into the units under test

– Hazardous voltages can occur on Fieldbus networks due to switching noise from motors and relays

– Some basic diagnostic equipment (e.g. a laptop) may not have the same rigorous levels of interface

protection as industrial equipment

In a USB to UART interface, there are two possibilities, either the USB interface can be isolated, or the UART interfaces (RS-232/RS-485/RS-422) can be isolated. In theory, both could be isolated inorder to protect the interface module itself from either equipment, or to provide safety isolation from two basic isolation interfaces in series.

Isolating using iCoupler Digital Isolators

Digital isolators using iCoupler technology offer high levels of robustness for galvanic isolation, with lower power requirements than opto-couplers and enhanced reliability. Other IC functionality (e.g.transceivers) can be integrated into single-chip solutions requiring little extra PCB area compared to non-isolated solutions. This is a particular advantage for isolating RS-232 or RS-485 interfaceswhere an IC is already required to transmit and receive at the appropriate voltages.

For USB, two signals, D+ and D-, need to be isolated transparently in order not to interfere with USB handshaking or require custom software drivers. Using a digital isolator for USB such as ADuM3160 achieves this in a wide-body SOIC footprint. Power is available on one side of the isolator, across the USB cable, and so a similar power supply should be provided on the isolated side as well. Using isoPower, a similar chip-scale transformer technology for power isolation, such a power supply can also be realized in a wide-body SOIC footprint, using the ADuM5000. If additional levels of power are required, an external transformer and rectifier can be used, requiring a transformer driver and a secondary regulator – which are combined in the ADuM3070.

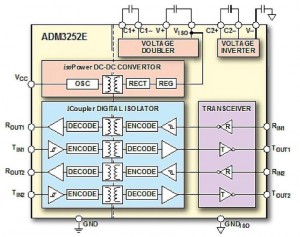

In order to isolate RS-232, a transmit (TX) and a receive (RX) signal require isolation, in addition to some control signals (e.g. RTS and CTS). However, in addition to a TTL interface to the UART, an RS-232 transceiver is required to convert these signals to/from the RS-232 voltage levels. An isolated power supply is also required to power the transceiver and the transceiver side of the isolator. All three components (signal isolation, transceiver and isolated power) are combined in theADM3252E as shown in Figure 2, resulting in a single BGA footprint to provide a complete isolated RS-232 interface.

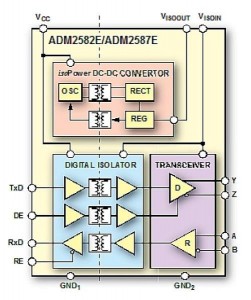

RS-485 also requires a transceiver to interface with either a two wire bus (A and B) or four wire bus (A, B, Y and Z). The signals to be isolated are transmit (TxD), receive (RxD), driver enable (DE) and receiver enable (/RE). Similar to the RS-232 solution, the ADM2587E provides a fully isolated RS- 485 interface as shown in Figure 3, including the integrated isoPower DC-DC converter required to power the transceiver side of the device. The transceiver can also be used for RS-422 communication.

Options for isolated USB to Industrial Serial Interfaces

Options for isolated USB to Industrial Serial Interfaces In order to interface with serial ports on industrial equipment, the RS-232, RS-422 or RS-485 transceivers must be combined with a USB to UART chip, for example, the FTDI FT2232H.

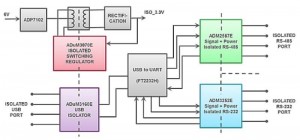

Isolation can be provided separately at multiple serial interfaces, for example, an RS-232 port using ADM3252E and an RS-485 port using ADM2587E; both hosted on the same USB connection. This has the advantage of isolating the two ports from each other, reducing potential hazards when connecting to two pieces of industrial equipment. In addition, no distinct isolated power supply is required, as the interface-side power supplies are generated internally using isoPower technology, in both the ADM3252E and ADM2587E.

Alternatively, the isolation can be located easily at a single point using the ADuM3160 or ADuM4160 USB isolators. This means standard serial interface ICs can be used. However, the ports are not individually isolated, and an isolated power supply solution (such as the ADuM3070) is required to supply the USB to UART chip, the transceivers and the downstream side of the USB isolator.

Both approaches are demonstrated on a single board in the reference circuit CN-0373, shown in figure 4. This combines ADuM3160 to isolate the USB interface, ADuM3070 to provide isolated power to the board including the USB to UART chip, and ADM3252E & ADM2587E to isolate RS-232 and RS-422/485 interfaces respectively.

Conclusions

Galvanic isolation is an essential component in interfacing to equipment in an industrial

environment. Digital isolators using iCoupler technology allow this to be integrated with the ICs

already needed to access industrial serial interfaces, as well as allowing transparent isolation of USB

interfaces. This allows a complete isolated USB to serial implementation for industrial applications.

In order to illustrate the possible isolation solutions for this application, Analog Devices has provided

a Circuit Note, CN-0373: Isolated USB to Isolated RS-485/Isolated RS-232 Interface. This fully

isolates a USB to UART chip both at the USB interface and at the RS-232 and RS-485 ports, allowing

full testing and demonstration of the robustness offered.